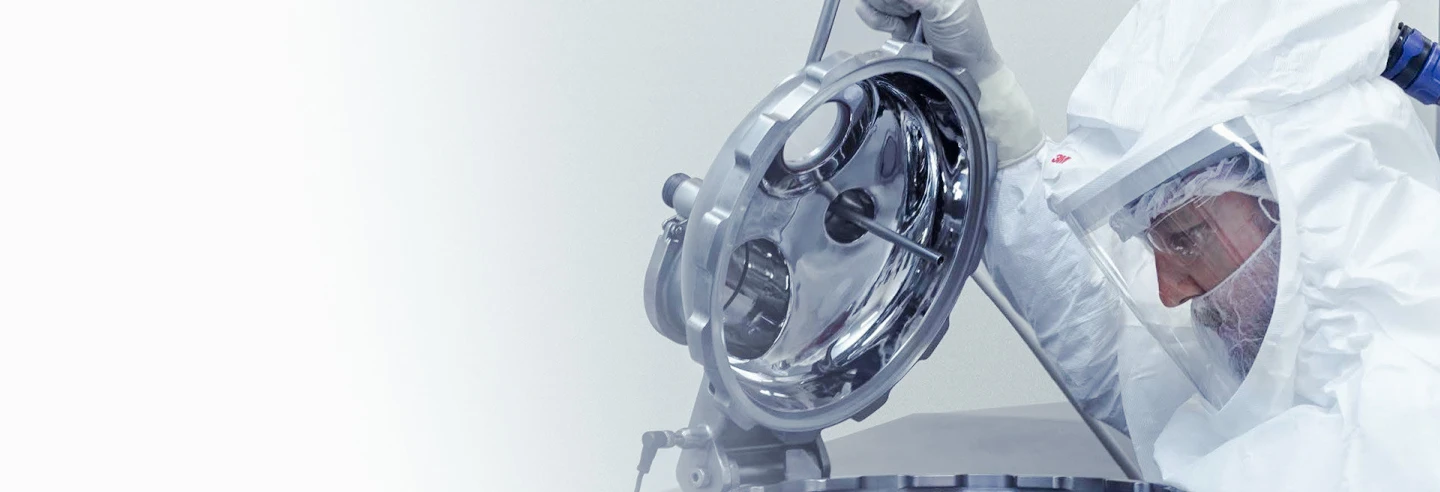

Welcome to the ACG Process Development Lab

A space dedicated to the collaborative pursuit of making the world healthier.

Available to all ACG customers, here you will find some of the world’s newest and most innovative pieces of process equipment, and experts in all aspects of process development.

A modern crafted laboratory.

Spread over 4,500 square feet of ACG Engineering space with world-class features:

Extensive range of equipment for feasibility, R&D and pilot scale studies

In-house technical training

A highly skilled team of 15+ pharmaceutical experts with experience handling 3,500+ formulations.

Equipped with in-process laboratory to monitor physical parameters

A lab designed with you in mind.

For more than two decades, ACG Engineering has been helping customers refine their process solutions.Together we’ve tried and tested methods and developed the process for thousands of formulations along the way, and even pioneered the first granulation technology that can both dry and granulate at the same time.

Our Process Development Lab is the next step in supporting our customers on their product journeys by providing world-class process development experience and technologies under one roof.

Test

We’ve enabled support trials in thousands of formulations over the years, and all over the world. In our Process Development Lab you can set your product at R&D and pilot scale, before replicating it at your manufacturing site.

Develop

Using our scientific resources, we can help you develop an existing process to work optimally or create a niche one. Our Lab has the in-house capabilities to support you from R&D to pilot stage. Tangential Spray Granulation, Hot Melt Granulation and Rotor Dry Powder Layering are just some novel process technologies we’ve developed.

Create

With experience of handling over 3,500 formulations, and technical experts in a wide range of specialisms, we can help you develop a product and provide value-added solutions, with extended on-site support for commercial set-up and production.

Optimise

ACG laboratories is well equipped to support you in completing QbD trials in product development. Our experts will facilitate you to reduce your development cycle, resources, and process time. We do this by helping to build robustness in the process and helping you to achieve a high success rate in commercialisation.

Scale up

We can test the scaling up of your project using pilot-scale machinery and providing practical tips on how to apply it to a commercial setting. ACG is also well equipped with technical capability to support you for successful scale out of the product during product validation and commercialisation stage.

Regulatory support

Helping you speed up the approval process, our team has vast experience in handling process and machine related queries.

Learn

Our training sessions are always in demand. You can learn about the process industry. See new formulations in action. Or have a 1-1 training session with some the latest equipment.

Meet the process experts.

As far as we’re concerned, it’s not just about the lab or the machines (although we have to say they are pretty impressive). It’s also about our people.

Our team has been working in the pharmaceutical and nutraceutical industries for years. Yes, they know all about the latest technologies, but – more importantly – they know how to work together, and with you. This means you’ll always get the absolute best process solutions and help in developing your products.

Dr Jitendra Amrutkar

Dr Jitendra Amrutkar brings over 19 years of experience in pharmaceutical industry, specialising in formulation development, polymer sciences, and excipient technologies. His expertise encompasses technical-commercial roles, application lab operations, and hands-on support for commercial manufacturing. With a Ph.D. in Pharmaceutical Sciences, he has extensive experience in formulation development, process development, technology transfer, troubleshooting, and providing support for the commercial manufacturing of solid oral dosage forms. A recognised thought leader in his field, Dr Amrutkar holds two patents and has authored over 30 research papers and presentations internationally. Prior to joining ACG, he led R&D and technical services teams at Ideal Cures, Evonik, Dr Reddy’s Laboratories, and Alembic, where he spearheaded the development of complex generics and novel formulations for global markets.

Prashant Deshpande

Prashant has over thirty-five years of experience in the pharmaceutical industry across operations and technical services in globally renowned organisations where he was instrumental in launching innovative formulations and establishing processes with great success. With his guidance ACG Laboratories has introduced several new technologies. He holds a Master of Pharmacy in pharmaceutical technology from Nagpur University.

Dr Rahul Aware

With over fifteen years of industrial pharmaceutical experience, Dr Aware has created two patents, more than thirty international poster presentations, two chapters in reputed books, and more than seven published articles in international journals. A recipient of the G.M. Abhyankar Research Award, Dr Aware maintains collaboration with universities in Germany, California and Singapore. Dr Aware leads ACG Laboratories and heads up the process technology support arm of ACG Engineering. His core area of expertise is wet granulation and drying technology.

Ramlu Koli

A Chemistry graduate from the Royal College in Mumbai, Ramlu has twenty-six years’ experience, many in process technique. Ramlu is FDA approved in tabletting and liquids, has helped develop many formulations, and specialises in tableting and liquids, Wurster technology, tablet coating, granulation and drying. Ramlu joined the ACG team in 2005.

Rupesh Malap

Rupesh has over nineteen years of work experience, with fifteen of those at ACG. Prior to joining us, he worked for Hindustan Biologicals, Swift Chemicals Pvt Ltd and Bee Pharma Pvt Ltd. As a chemistry expert, with a BSc from Mumbai University and an MSc from Vinyaka Missions University, Rupesh has a wealth of experience in developing and testing formulations.

Brahmadev Chaurasiya

After graduating with a BSc, Brahmadev became a postgraduate in Industrial Analytical Chemistry and a Master of Science. He’s worked in the pharma industry for over eighteen years and has developed a vast amount of experience developing and optimising process formulations. Ask him about anything to do with tablet coating. Brahmadev can often be found conducting onsite trials or leading one of our training programmes.

Suraj Datir

Suraj has been part of the process development team for the past thirteen years and came to ACG with a strong pharmaceutical background (as well as an MBA in Operation Management). He specialises in process support and coordination for our FBE, SmartCoater and HSMG equipment.

Pankaj Samrit

Pankaj was educated with a B. Pharm at BA&KR College of Pharmacy before going on to obtain an MBA in Industrial Management. Pankaj spent seven years gaining experience in the pharmaceutical industry before becoming a member of our lab team five years ago. He specialises in process support and coordination in fluid bed drying (FBE) and is an expert in ACG’s SmartCoater, compression and capsule machines, as well as in our high shear mixing (HSM) granulators.

Rahul Hawaldar

Rahul began his career at ACG, straight out of Tatyasaheb Kore College of Pharmacy where he earned a BSc in Pharmacy. He also spent eleven years working with ACG Engineering, before returning to ACG to work in our process department. Rahul has a particular specialism in pharmaceutics dosage design.

Rakesh Chikane

Rakesh first joined us twelve years ago, fresh out of Bhavans Hazarimal Somani College in Mumbai, with a BSc in Chemistry. He is our go-to person for anything regarding fluid bed drying (FBE) top spray granulation, hot stage microscopy (HSM) granulation, close loop GT line, Wurster application, tablet coating processes and troubleshooting.

Pravin Ghadage

Pravin trained as an ITI Fitter at Maharashtra Technical Institute before gaining employment as a technician at Sai Solutions. He went on to hone his expertise at Thurs Organics before joining the team at ACG. When it comes to running a laboratory, Pravin has a vast amount of knowledge and is always eager to put his skills into practice.

Prashant Pisal

After graduating with a Masters from Poona College of Pharmacy in Pune, Prashant spent twelve years becoming an expert in formulation and R&D. During that time, he has developed and commercialised many formulations for the USA and both regulated and domestic markets. His development achievements range from delayed-release capsules and tablets to suspension and liposomal dosage forms. Prashant has been published twice in international industry journals.

Discover our machines.

The ACG Process Development Lab is home to some of the smartest technologies and finest powder processing equipment.

As they have often been developed in direct response to customer needs, many of our Lab machines are unique.

Process EQUIPMENT

The Lab is fully equipped with a wide range of process equipment for drying, granulation and tablet coating.

MINIQUEST F

“Big on innovation. Capable of handling the smallest quantities.”

MINIQUEST T

“Big on innovation. Capable of handling the smallest batches.”

QUEST FB

“A table-top machine for all fluid bed-based experiments.”

GPCG 1.1

“The legacy lab workhorse for all things fluid bed.”

FBE5

“The fluid bed for when you need a little extra.”

QUEST HSM II

“A compact and compliant, high shear mixer.”

PILOT SCALE EQUIPMENT

Using our pilot scale equipment, you can test the feasibility of scaling up before taking your product to market. Our experts will support you through the process and beyond.

GT 150 X·ONE

State of the art granulation and drying system in one.

PROTAB 300

“Tableting simplified.”

QUEST TC

“Table top lab-scale tablet coating studies.”

QUEST TC III

“Versatility in lab and pilot coating studies.”

Get in touch.

Why not consider including the ACG Process Development Lab as part of your product journey? We can help at any stage, but if you get in touch at the beginning (when you’re filing a new product) we can help you save time and money on getting it right first time.

Make process development part of your product journey today.