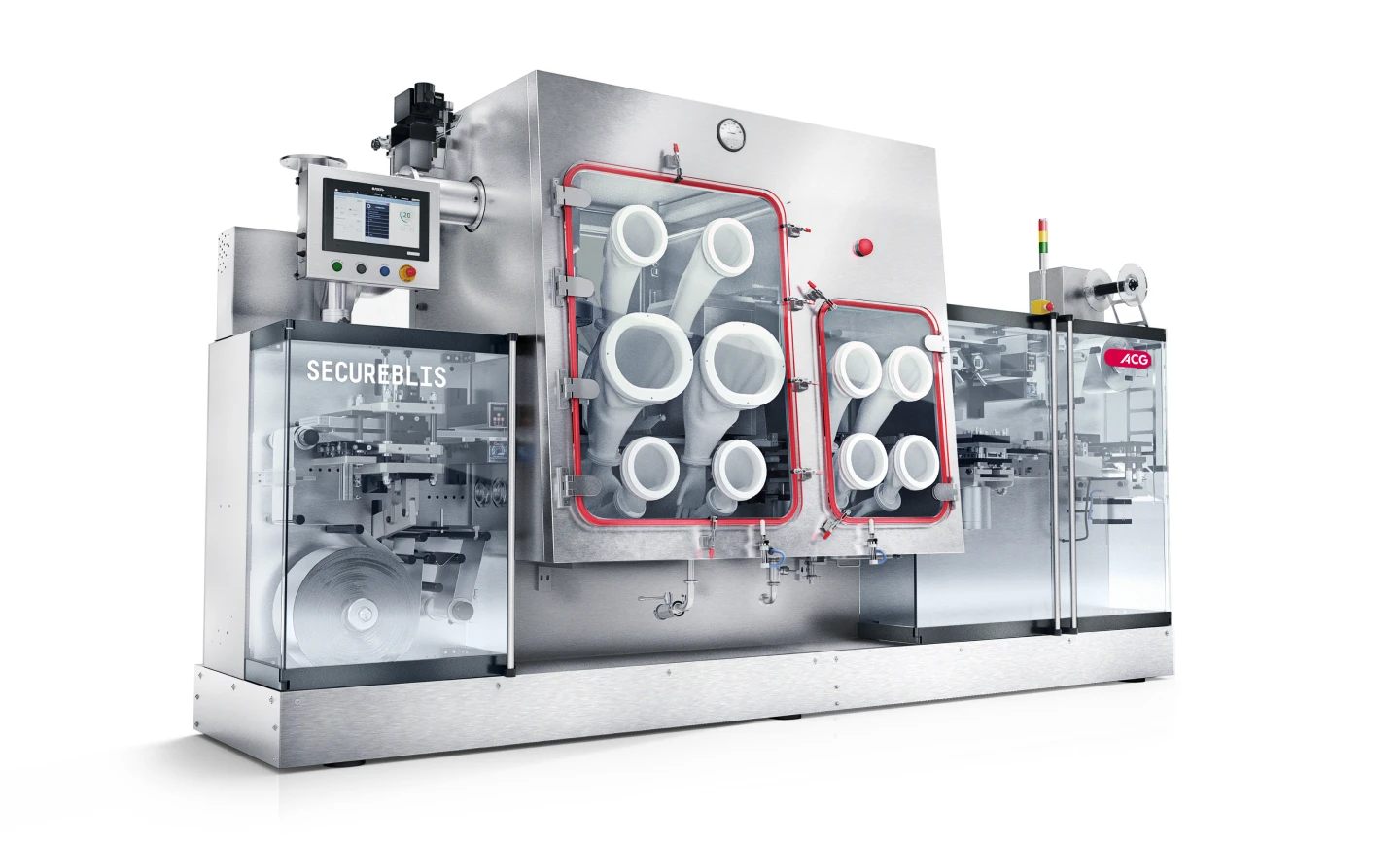

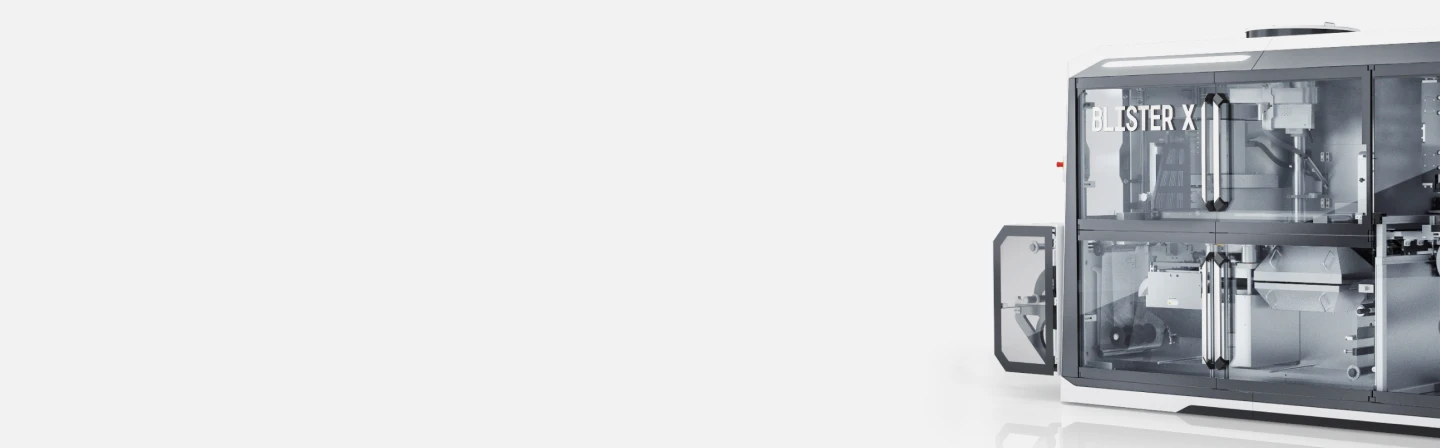

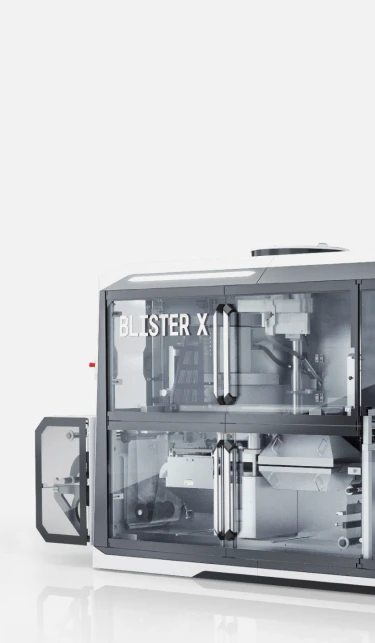

About the BLISTER X

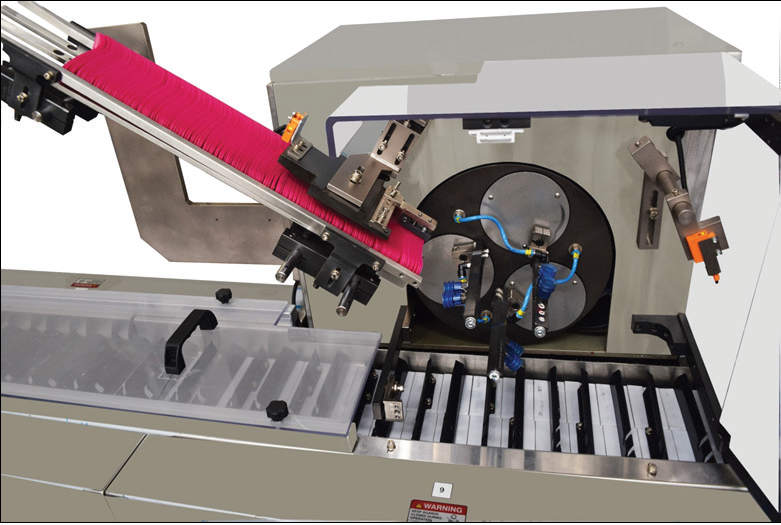

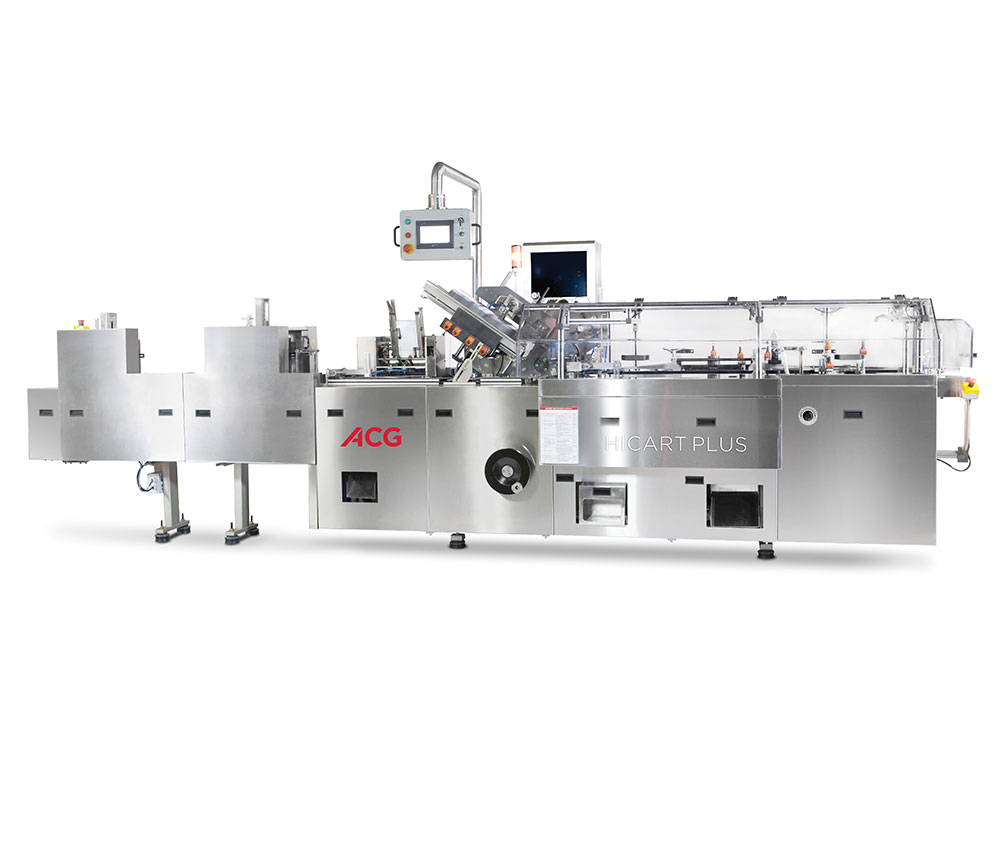

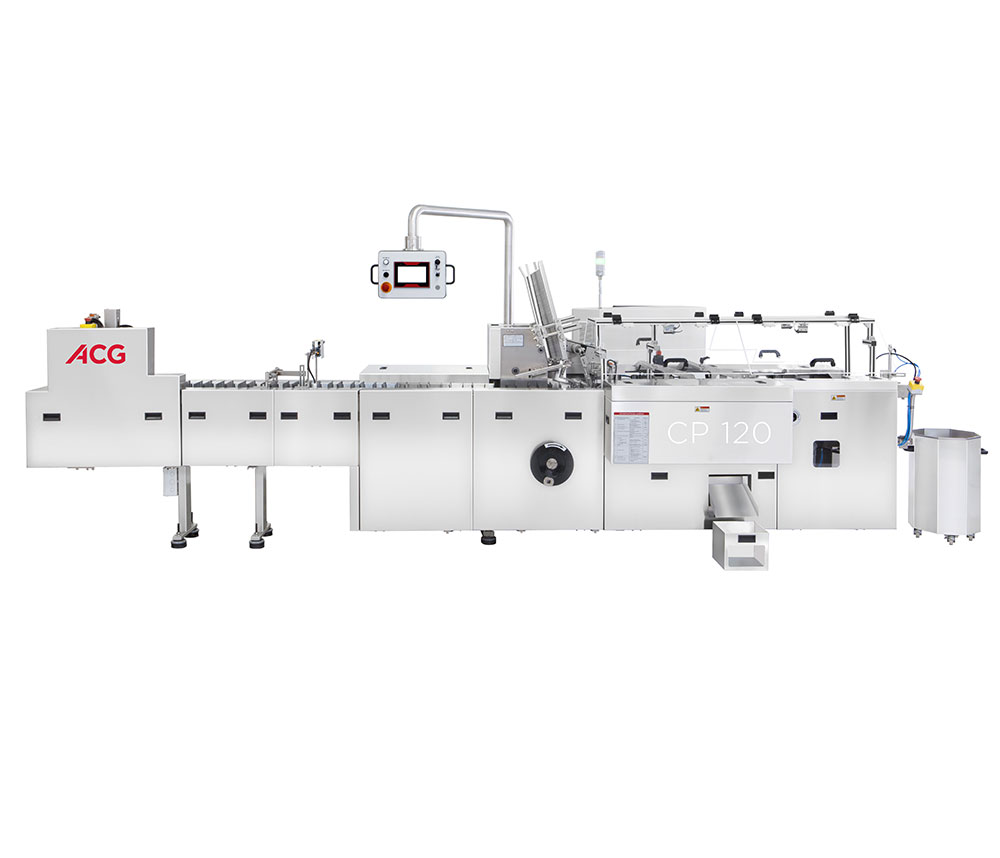

A next-generation flat-forming, rotary-sealing, continuous-motion high-output blister packaging machine, BLISTER X, is powerhouse for both large manufacturing and campaign batches. It’s designed with large forming areas for faster forming cycles and is completely servo-controlled, ensuring reliability, flexibility, and productivity of high-quality blister packs consistently.

BLISTER X's streamlined design exudes sophistication and advanced technology, making it functionally superior and visually striking for any manufacturing environment.

| Features | Benefits | |

|---|---|---|

Three-stage heating for film forming | Strict control of ±2.5°C of specified temperature reduces film shrinkage

Ensures the formation of well-defined blister cavities with uniform thickness

Avoids abrupt temperature fluctuations | |

Completely servo-controlled forming, even for cold-form blisters | Enhanced accuracy improving quality, productivity, and life of the machine | |

Servo-controlled rotary vibrator feeding mechanism with high angular velocity | Enhanced feeding efficiency for higher output even at rated cycles | |

Independently servo controlled sealing and counter sealing roller | Superior sealing quality with diamond-type sealing of cold-form and thermoform blisters

Accuracy in both sealing and PRC (print registration control) applications | |

High-speed punching | Significantly higher output, with up to three tracks of blister and combi-packs

Eliminates the limitations of punching in high-speed blister applications | |

High-speed servo-controlled blister dropping | Seamless line integration ensures blister packs land accurately on the conveyor belt and facilitate full integration with cartoning machinery | |

Large format area (276 mm x 220 mm) | Offers flexibility to produce high output in various combinations – single/twin/three track and combi packs |

Features & Benefits

Three-stage heating for film forming

Strict control of ±2.5°C of specified temperature reduces film shrinkage

Ensures the formation of well-defined blister cavities with uniform thickness

Avoids abrupt temperature fluctuations

Completely servo-controlled forming, even for cold-form blisters

Enhanced accuracy improving quality, productivity, and life of the machine

Servo-controlled rotary vibrator feeding mechanism with high angular velocity

Enhanced feeding efficiency for higher output even at rated cycles

Independently servo controlled sealing and counter sealing roller

Superior sealing quality with diamond-type sealing of cold-form and thermoform blisters

Accuracy in both sealing and PRC (print registration control) applications

High-speed punching

Significantly higher output, with up to three tracks of blister and combi-packs

Eliminates the limitations of punching in high-speed blister applications

High-speed servo-controlled blister dropping

Seamless line integration ensures blister packs land accurately on the conveyor belt and facilitate full integration with cartoning machinery

Large format area (276 mm x 220 mm)

Offers flexibility to produce high output in various combinations – single/twin/three track and combi packs

Technical specification

| Forming cycle | Thermoforming | 55 cycles/min |

| Cold-forming | 45 cycles/min | |

| Maximum blister size (mm) | 276 mm x 220 mm | |

| Forming depth | <12 mm | |

| Forming materials | PVC, PVC/PVdC, Aclar, Triplex (PVC/PE/PVdC), cold-form foil (Alu) | |

| Lidding materials | Push-through and child-resistant foil/peelable paper | |

We make it better, so you can make better.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS