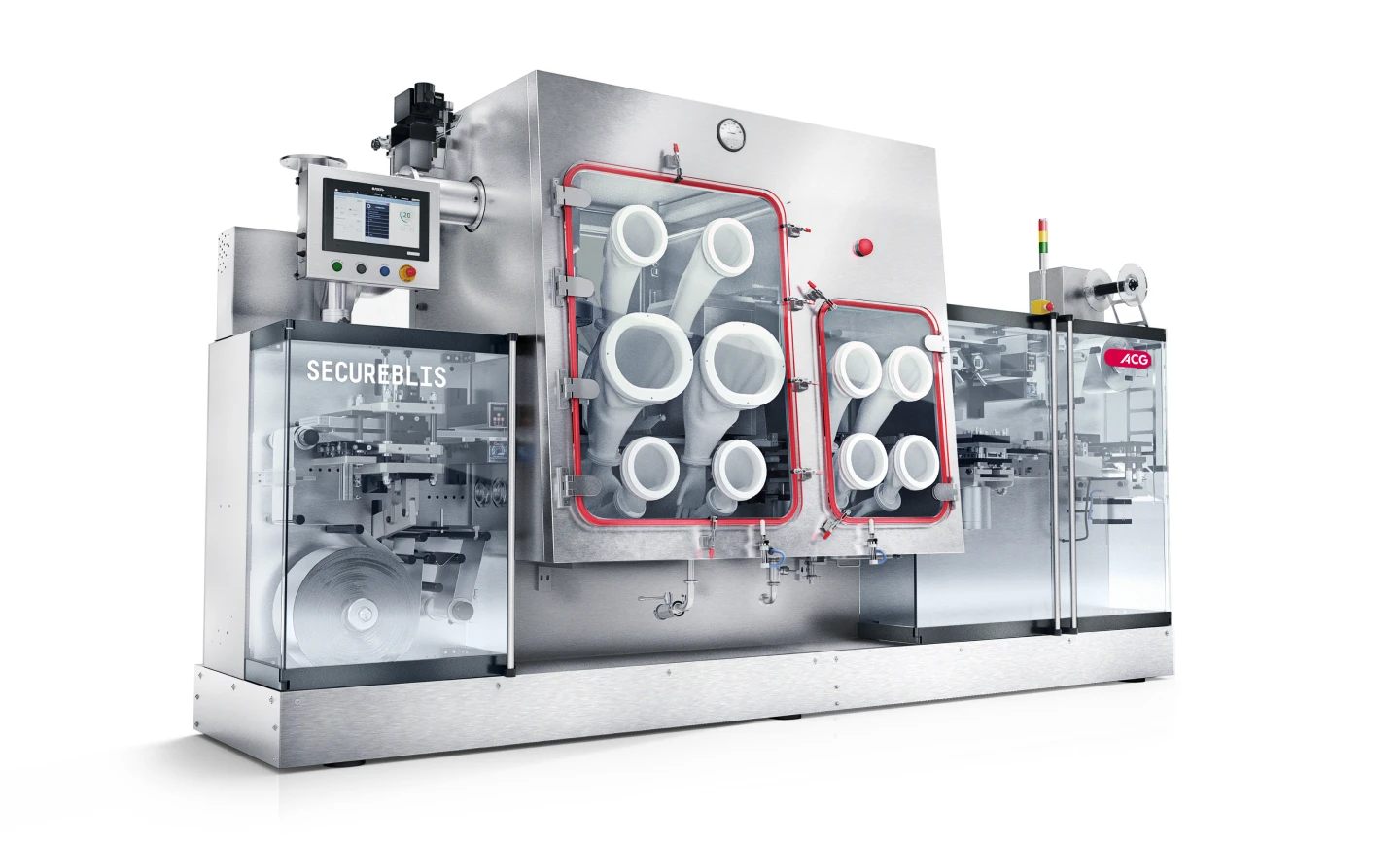

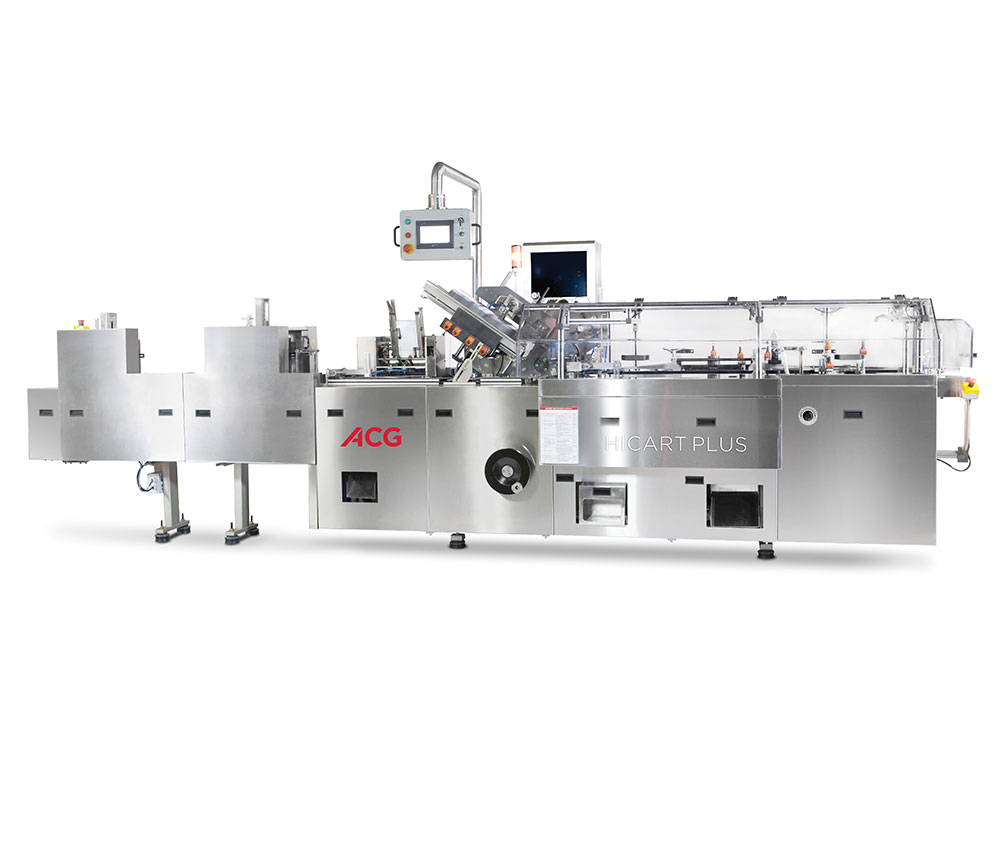

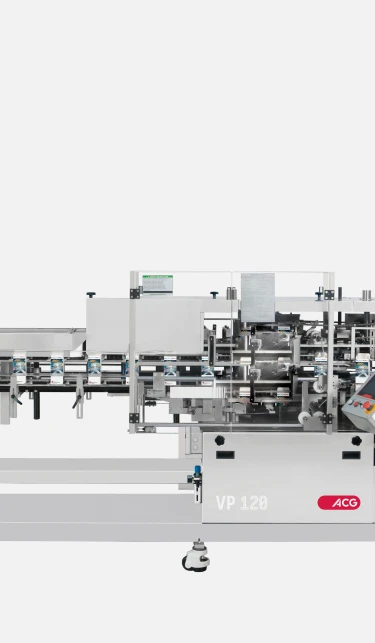

About the VP 120

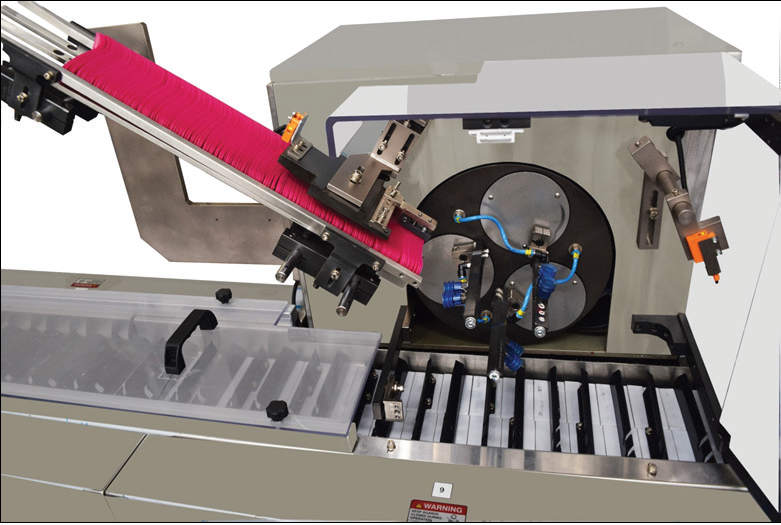

Versatile, continuous-motion and semi-automatic – ACG’s VP 120 vertical cartoning machine is designed specifically for handling standard rigid products, and non-rigid products, and combination products that other packaging machines simply can’t handle.

It enables the packing of multiple products in a single carton, and handles a wide range of carton sizes without additional format parts. It can also be fully automated for handling customised products.

Applications

Blister packs, bottles, vials, ampoules, tubes, tubes and toothbrushes, soaps, pouches, spoons

| Features | Benefits | |

|---|---|---|

Format-free cartoning | Proficiency in handling a wide range of carton sizes, with low investment and running costs | |

Caster wheels | Moves freely around the production area to optimise use of available space | |

Automated leaflet transfer system | Reduces manual work significantly | |

Option to extend product conveyor to match operator configuration | Flexibility to cater to different packaging applications | |

Pharmacode and barcode inspection | Supports compliance with regulatory norms |

Features & Benefits

Format-free cartoning

Proficiency in handling a wide range of carton sizes, with low investment and running costs

Caster wheels

Moves freely around the production area to optimise use of available space

Automated leaflet transfer system

Reduces manual work significantly

Option to extend product conveyor to match operator configuration

Flexibility to cater to different packaging applications

Pharmacode and barcode inspection

Supports compliance with regulatory norms

Technical specifications

VP 120 | ||

| Maximum output | 120 cartons/min | |

| Carton width | Min | 20 mm |

| Max | 135 mm | |

| Carton height | Min | 14 mm |

| Max | 90 mm | |

| Carton length | Min | 57 mm |

| Max | 320 mm | |

| Carton type | Reverse tuck-in, glued type, parallel tuck-in, top tuck-in/bottom gluing | |

Wherever in the world there's a medicine cabinet, we're almost certainly somewhere inside it.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS