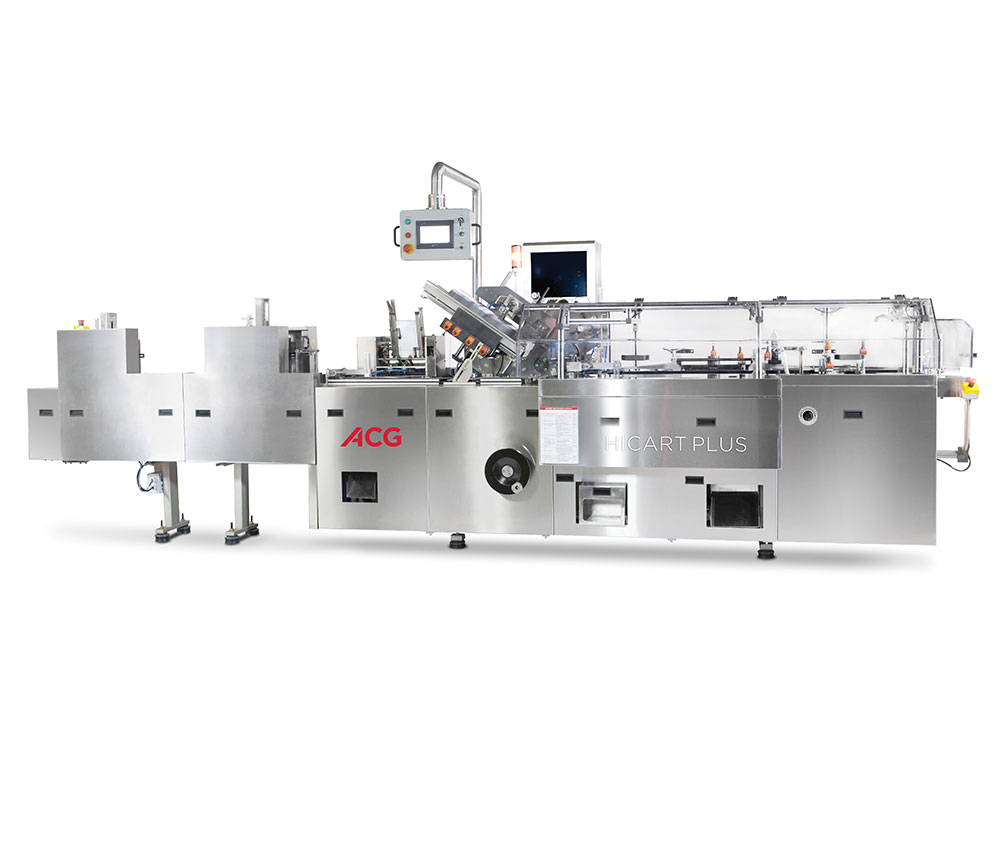

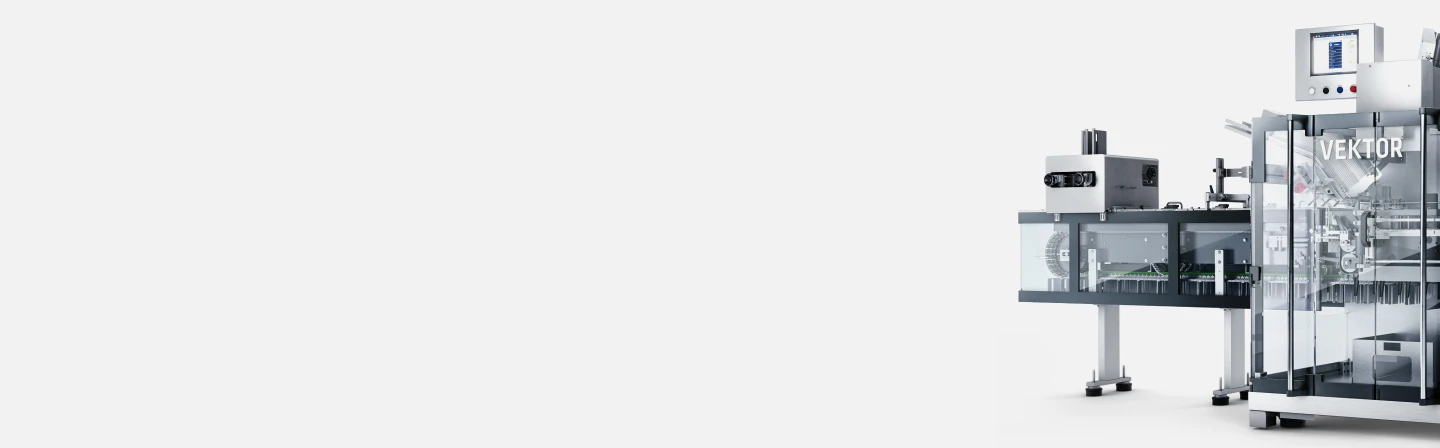

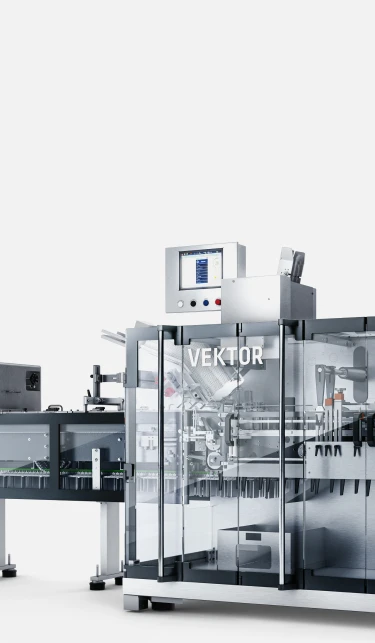

About the VEKTOR

VEKTOR is a compact, intermittent-motion, horizontal cartoning machine that integrates easily with upstream blister packaging machines. Built on a robust framework of balcony design, it’s cGMP compliant, and ideal for blister applications with multiple stacks.

Applications

Multiple stacks of blister packs

| Features | Benefits | |

|---|---|---|

Servo motion-controlled product pusher | Ensures precise product pushing and provides unobstructed rear-side visibility

Performs accurate height verification, and automatically rejects empty cartons | |

Compact footprint | Saves production floorspace | |

cGMP-compliant balcony-type construction built on a servo-driven platform | Easy access and cleaning | |

Single format part | Quick and easy changeover | |

Built-in ‘No product-No leaflet-No carton’ system | Reliable, error-free output | |

Available in different pitch configurations | Package cartons of many different sizes | |

Capable of integrating leaflet and booklet transfer units | Allows patient information inserts in different formats |

Features & Benefits

Servo motion-controlled product pusher

Ensures precise product pushing and provides unobstructed rear-side visibility

Performs accurate height verification, and automatically rejects empty cartons

Compact footprint

Saves production floorspace

cGMP-compliant balcony-type construction built on a servo-driven platform

Easy access and cleaning

Smooth and silent operation

Single format part

Quick and easy changeover

Cost-effective

Built-in ‘No product-No leaflet-No carton’ system

Reliable, error-free output

Available in different pitch configurations

Package cartons of many different sizes

Capable of integrating leaflet and booklet transfer units

Allows patient information inserts in different formats

Technical specifications

VEKTOR 5P | VEKTOR 8P | ||

| Maximum output | 80 cartons/min | 50 cartons/min | |

| Carton width | Min | 20 mm | 50 mm |

| Max | 95 mm | 130 mm | |

| Carton height | Min | 16 mm | 16 mm |

| Max | 90 mm | 100 mm | |

| Carton length | Min | 65 mm | 65 mm |

| Max | 200 mm | 220 mm | |

| Carton type | Reverse tuck-in, glued type, parallel tuck-in, front tuck-in/rear gluing, gluing after tuck-in | Reverse tuck-in | |

Always getting better at helping make people better.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS