About the SECUREFILL 40T

The SECUREFILL series is our high-level containment capsule-filling machine range. It’s designed for filling capsules with highly potent drugs, and complies with occupational exposure band (OEB) up to level 4. Built with operator safety in mind, these machines are equipped for filling capsules with oncological, hormonal, biopharmaceutical, antiviral formulations, and other formulations containing highly potent active pharmaceutical ingredients (HPAPIs).

SECUREFILL 40T works best for medium-size to large production batches.

Applications

Containment filling of pellets, tablets, micro-tablets, capsules, soft gels, and their combinations in capsules

| Features | Benefits | |

|---|---|---|

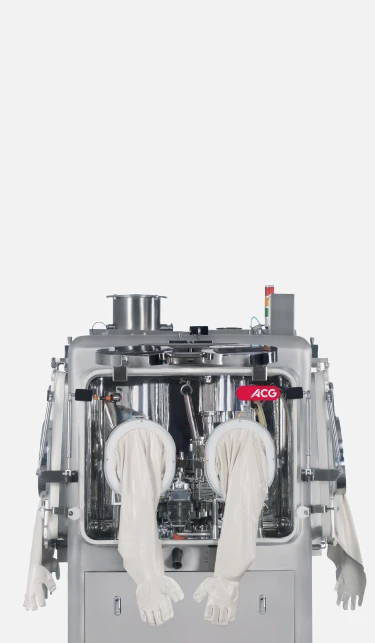

Constructed as a monoblock SS316L structure featuring HEPA filters, a rapid transfer port (RTP), and glove ports, all maintained under negative pressure to ensure contained handling of drug products | Ensures complete containment, thereby avoiding operator contact within OEL range 1-10 µg/m3 | |

Provision for contained charging and discharging | Integrated containment philosophy for upstream and downstream processes. | |

Wet-in-place system to ensure wetting of all suspended particles in the pharma zone | Protects the operator and the operational environment from formulation residues – and enables easy cleaning | |

Certified for highly potent and cytotoxic drugs requiring OEB up to 4 | Supports the production of life-saving drugs that contain HPAPIs, such as oncology products | |

Can be integrated with check-weighers, metal detectors, capsule sorters, and de-dusters under containment conditions | Ensures safe production of high-quality capsules |

Features & Benefits

Constructed as a monoblock SS316L structure featuring HEPA filters, a rapid transfer port (RTP), and glove ports, all maintained under negative pressure to ensure contained handling of drug products

Ensures complete containment, thereby avoiding operator contact within OEL range 1-10 µg/m3

Provision for contained charging and discharging

Integrated containment philosophy for upstream and downstream processes.

Wet-in-place system to ensure wetting of all suspended particles in the pharma zone

Protects the operator and the operational environment from formulation residues – and enables easy cleaning

Certified for highly potent and cytotoxic drugs requiring OEB up to 4

Supports the production of life-saving drugs that contain HPAPIs, such as oncology products

Can be integrated with check-weighers, metal detectors, capsule sorters, and de-dusters under containment conditions

Ensures safe production of high-quality capsules

Technical specifications

| Capsule size | 00 - 5 |

| Maximum speed | 40,000 capsules/hr |

| OEL | 1-10 µg/m3 |

Also Available In

|

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS