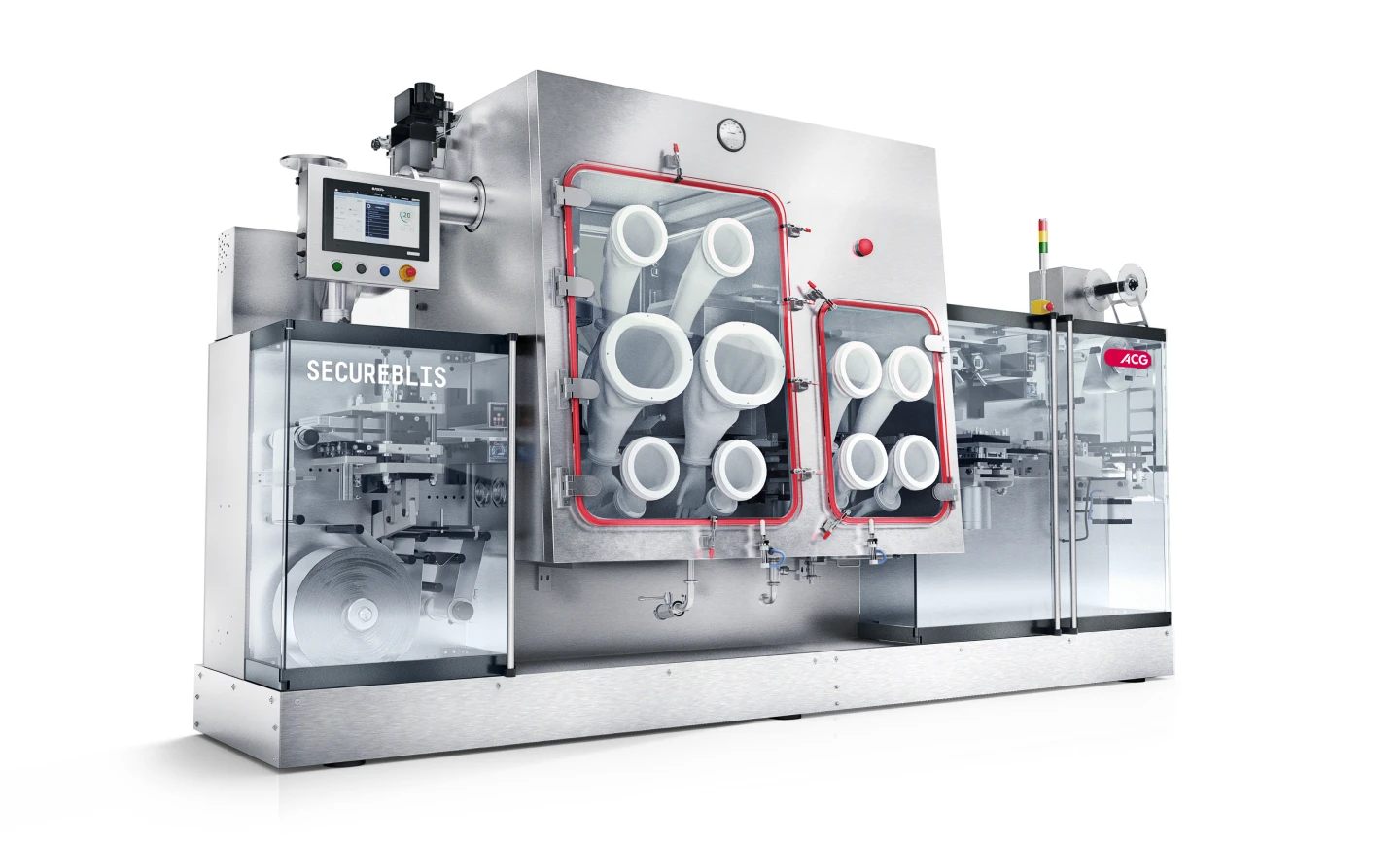

About the GTC III

The GTC III is an integrated granulation line that facilitates a seamless and efficient production flow of the entire granulation process. With OEB 5 compliance, GTC III is designed to prioritise containment and operator safety, optimising productivity, and ensuring quality, all while upholding stringent standards for product integrity and environmental protection. It is especially suitable for the granulation of oncological, hormonal, biopharmaceutical, antiviral and other such HPAPIs (highly potent active pharmaceutical ingredients).

| Features | Benefits | |

|---|---|---|

A complete granulation line with OEB 5 compliance | Performs granulation to blending, ensuring the highest safety standards even for HPAPIs | |

Provisions for rapid transfer port, active transfer port and contained poly bag transfer | Facilitates charging of material in isolator without compromising integrity | |

A wide range of capacities (0.6 to 6 l) | Offers flexibility in batch sizes, tailored to your specific needs | |

Integrated wet and dry mills | Contained particle sizing of wet and dry granules creates a seamless processing experience, boosting safety, efficiency and productivity | |

Multiple glove ports | Ensures 100% accessibility and operator safety, promoting a secure and comfortable working environment | |

Flexibility to integrate the weighing scale inside the isolator | Easy online interface-based monitoring of binder solution spray rate

Streamlines your processes, enhancing accuracy and convenience | |

IPC-based control system with complete 21 CFR part 11 compliance | Ensures regulatory adherence and operational efficiency with audit trails, user management, recipe management, and batch reports | |

Strategically placed washing nozzles, along with handheld options | Provides thorough and efficient cleaning saving time and effort

Ensures operator safety | |

Optimised footprint | Maximises your available space, optimizing your facility layout and saving costs |

Features & Benefits

A complete granulation line with OEB 5 compliance

Performs granulation to blending, ensuring the highest safety standards even for HPAPIs

Provisions for rapid transfer port, active transfer port and contained poly bag transfer

Facilitates charging of material in isolator without compromising integrity

A wide range of capacities (0.6 to 6 l)

Offers flexibility in batch sizes, tailored to your specific needs

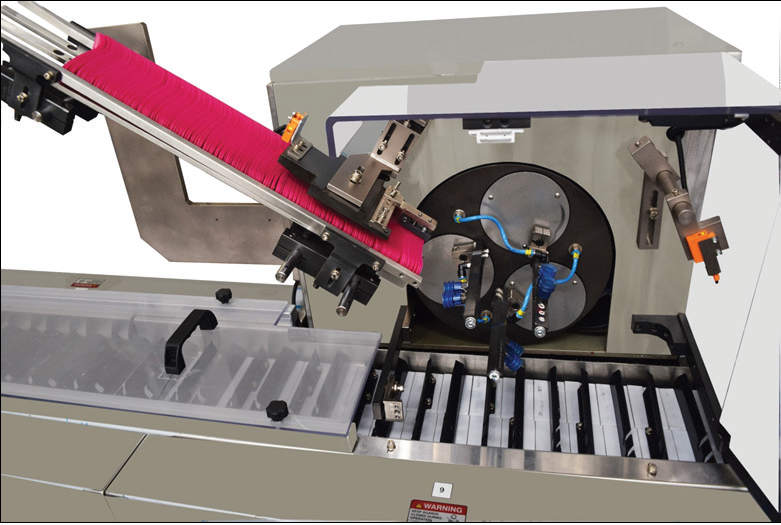

Integrated wet and dry mills

Contained particle sizing of wet and dry granules creates a seamless processing experience, boosting safety, efficiency and productivity

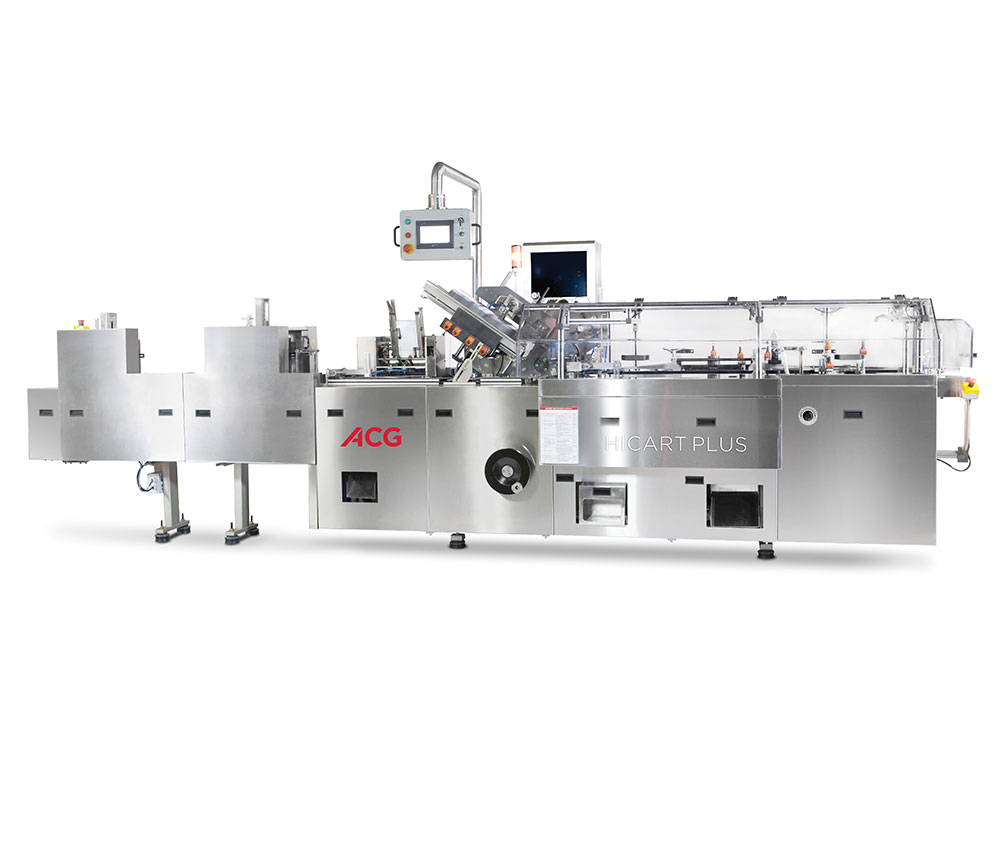

Multiple glove ports

Ensures 100% accessibility and operator safety, promoting a secure and comfortable working environment

Flexibility to integrate the weighing scale inside the isolator

Easy online interface-based monitoring of binder solution spray rate

Streamlines your processes, enhancing accuracy and convenience

IPC-based control system with complete 21 CFR part 11 compliance

Ensures regulatory adherence and operational efficiency with audit trails, user management, recipe management, and batch reports

Strategically placed washing nozzles, along with handheld options

Provides thorough and efficient cleaning saving time and effort

Ensures operator safety

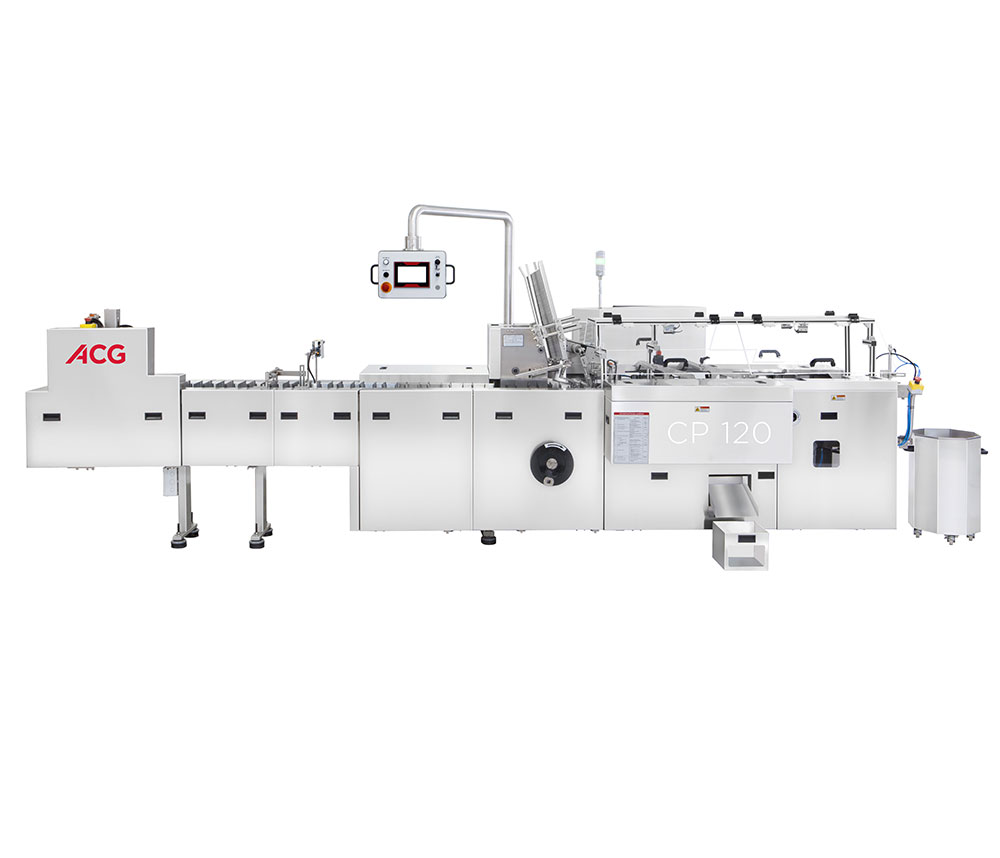

Optimised footprint

Maximises your available space, optimizing your facility layout and saving costs

You can’t have healthy people without a healthy planet.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS