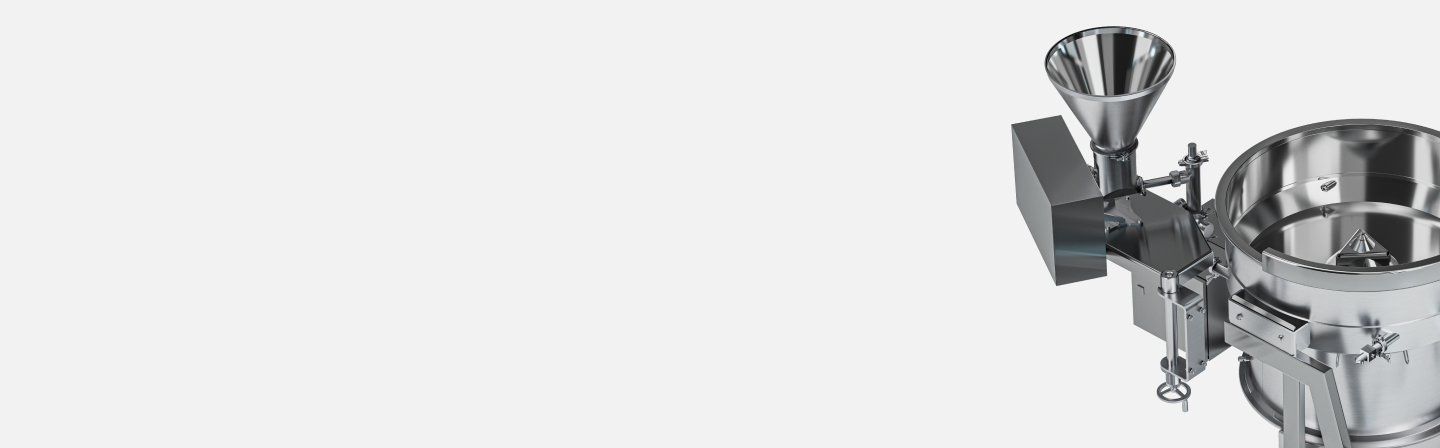

About the R series

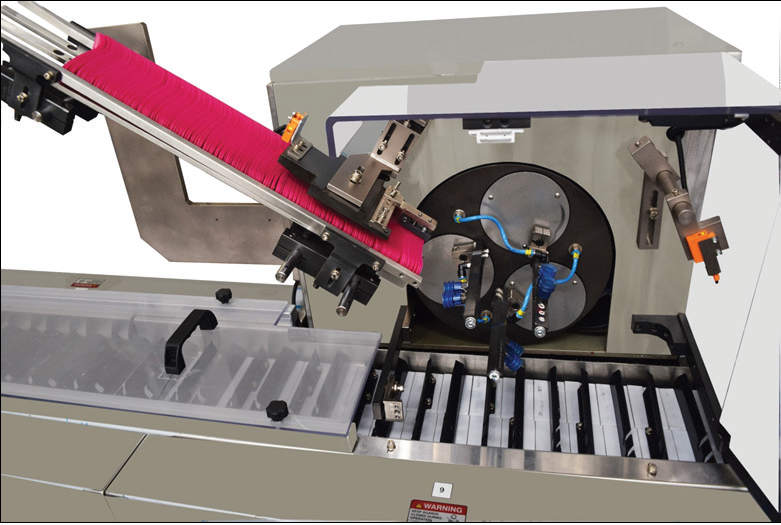

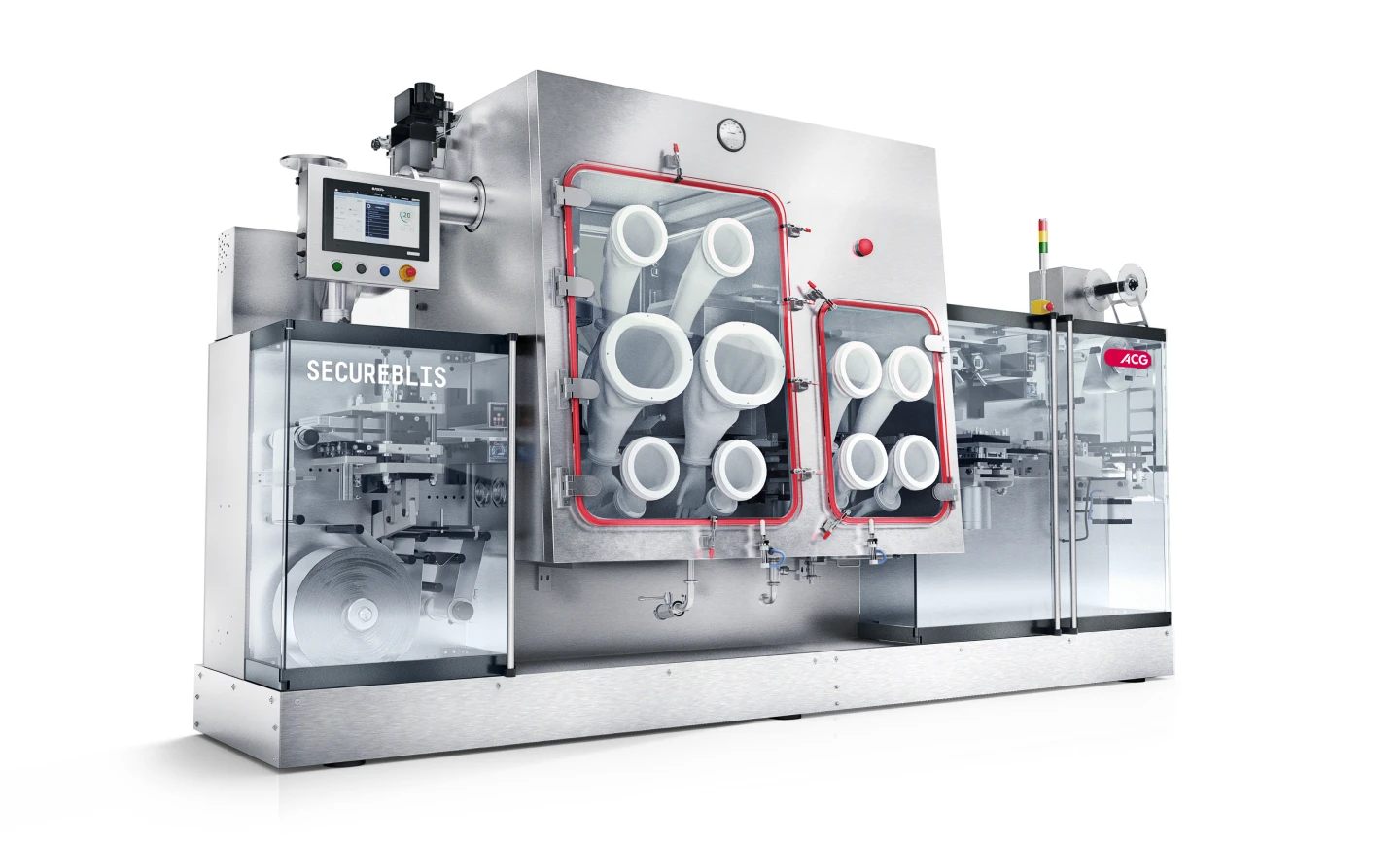

The R series rotor insert is the latest innovation in ACG’s fluid-bed machines. Combining different processes into a single container facilitates a wide range of applications, including pelletisation, dry-powder layering, rotor granulation/suspension coating, and spherical granulation. Ultimately, this ensures perfect-shaped pellets and high-density granules with narrow particle-size distribution. All this is backed by extensive process and optimisation support from our experts, who have collective experience and expertise in handling over 1,000 formulations.

Applications

Spheronisation/pelletisation, powder layering, and solution and suspension coating

| Features | Benefits | |

|---|---|---|

Plug-and-play versatility, with interchangeable inserts retrofittable to existing fluid-bed combination machines | Access to cutting-edge technology without additional investment | |

Highly accurate powder dosing system for a wide range of applications | Precise process control for drug layering and powder coating applications | |

Rotor discs for the full range of applications | Enables spheronisation and drug layering | |

Integrates easily with a wide variety of powder feeders | Offers flexibility and is suitable for multiple applications |

Features & Benefits

Plug-and-play versatility, with interchangeable inserts retrofittable to existing fluid-bed combination machines

Access to cutting-edge technology without additional investment

Highly accurate powder dosing system for a wide range of applications

Precise process control for drug layering and powder coating applications

Rotor discs for the full range of applications

Enables spheronisation and drug layering

Integrates easily with a wide variety of powder feeders

Offers flexibility and is suitable for multiple applications

Technical specifications

| R125 | R250 | R500 | GPCG 1.1 | R II | |

Working volume | Min | 15 l | 30 l | 45 l | 1.5 l | 2 l |

Max | 50 l | 100 l | 150 l | 4 l | 6 l | |

We make it better, so you can make better.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS