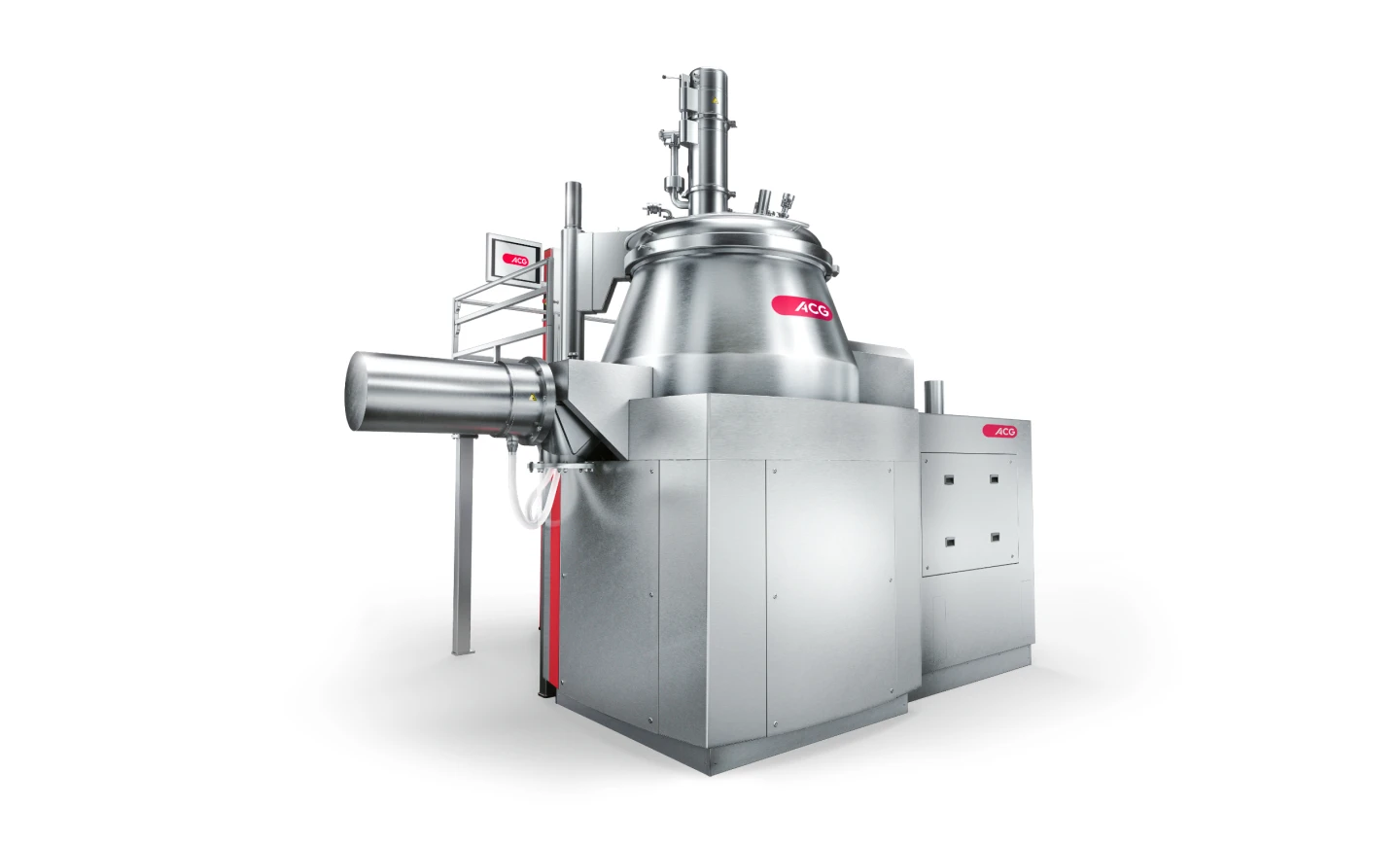

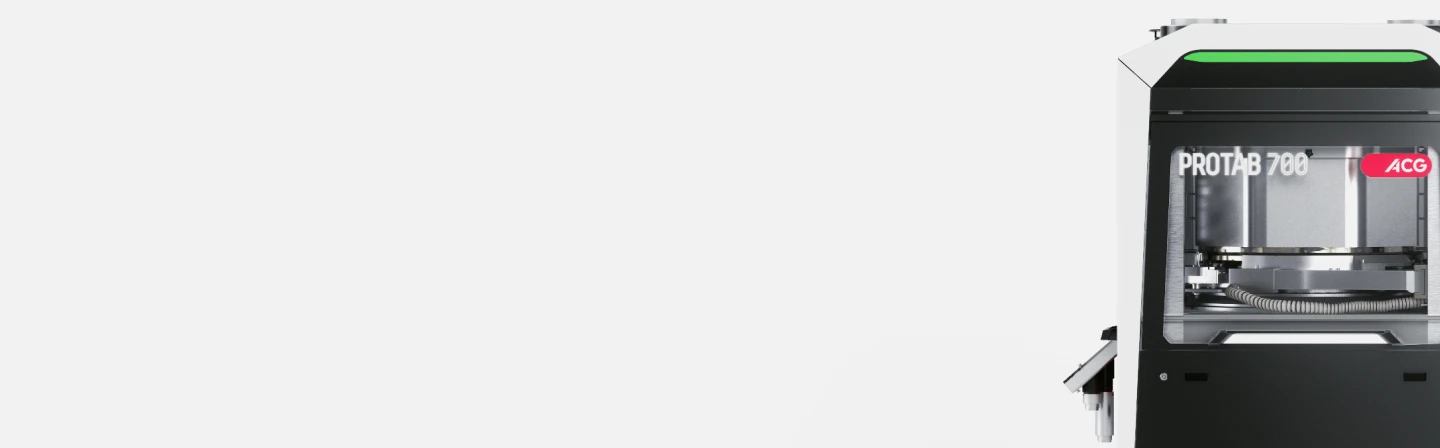

About the PROTAB™ 700

With PROTAB™ 700, ACG has pushed technological boundaries to simplify tablet compression. From basic functions to advanced processes, this double-rotary tablet-compression machine is all about absolute efficiency – without compromise. It’s designed with input from process experts, and is ideal for manufacturing large-scale campaign batches.

Applications

Monolayer and bilayer tablets

| Features | Benefits | |

|---|---|---|

Retrofittable bilayer kit | Produces bilayer tablets of the highest quality | |

Equipped with InstAmend technology | Detects and rectifies faulty punches immediately, and eliminates long process interruptions and unnecessary downtime | |

Interchangeable turret design | Flexibility of compressing various tablet sizes at varying speeds | |

Servo-based automatic weight control | Produces high-quality tablets of consistently precise weight | |

Sophisticated feeder design that achieves 100 g/feeder of leftover powder | Increased yield and reduced loss of valuable formulation | |

Toolless design of assemblies

Faster, simplified batch-to-batch changeover time of 60 minutes | Shorter production time due to faster, simplified batch-to-batch changeover | |

Individual layer-sampling and rejection of defective bilayer tablets | Easier sampling with no compromise on quality |

Features & Benefits

Retrofittable bilayer kit

Produces bilayer tablets of the highest quality

Equipped with InstAmend technology

Detects and rectifies faulty punches immediately, and eliminates long process interruptions and unnecessary downtime

Interchangeable turret design

Flexibility of compressing various tablet sizes at varying speeds

Servo-based automatic weight control

Produces high-quality tablets of consistently precise weight

Sophisticated feeder design that achieves 100 g/feeder of leftover powder

Increased yield and reduced loss of valuable formulation

Toolless design of assemblies

Faster, simplified batch-to-batch changeover time of 60 minutes

Shorter production time due to faster, simplified batch-to-batch changeover

Individual layer-sampling and rejection of defective bilayer tablets

Easier sampling with no compromise on quality

Technical specifications

| Punch type | D | B | BB | BBS | |

| Punch stations | 51 | 63 | 79 | 85 | |

| Output | Monolayer tablets | 489,600 tablets/hr | 604,000 tablets/hr | 758,000 tablets/hr | 816,000 tablets/hr |

| Bilayer tablets | 153,000 tablets/hr | 189,000 tablets/hr | 237,000 tablets/hr | 255,000 tablets/hr | |

| Maximum tablet diameter | 25 mm | 16 mm | 13 mm | 11 mm | |

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS