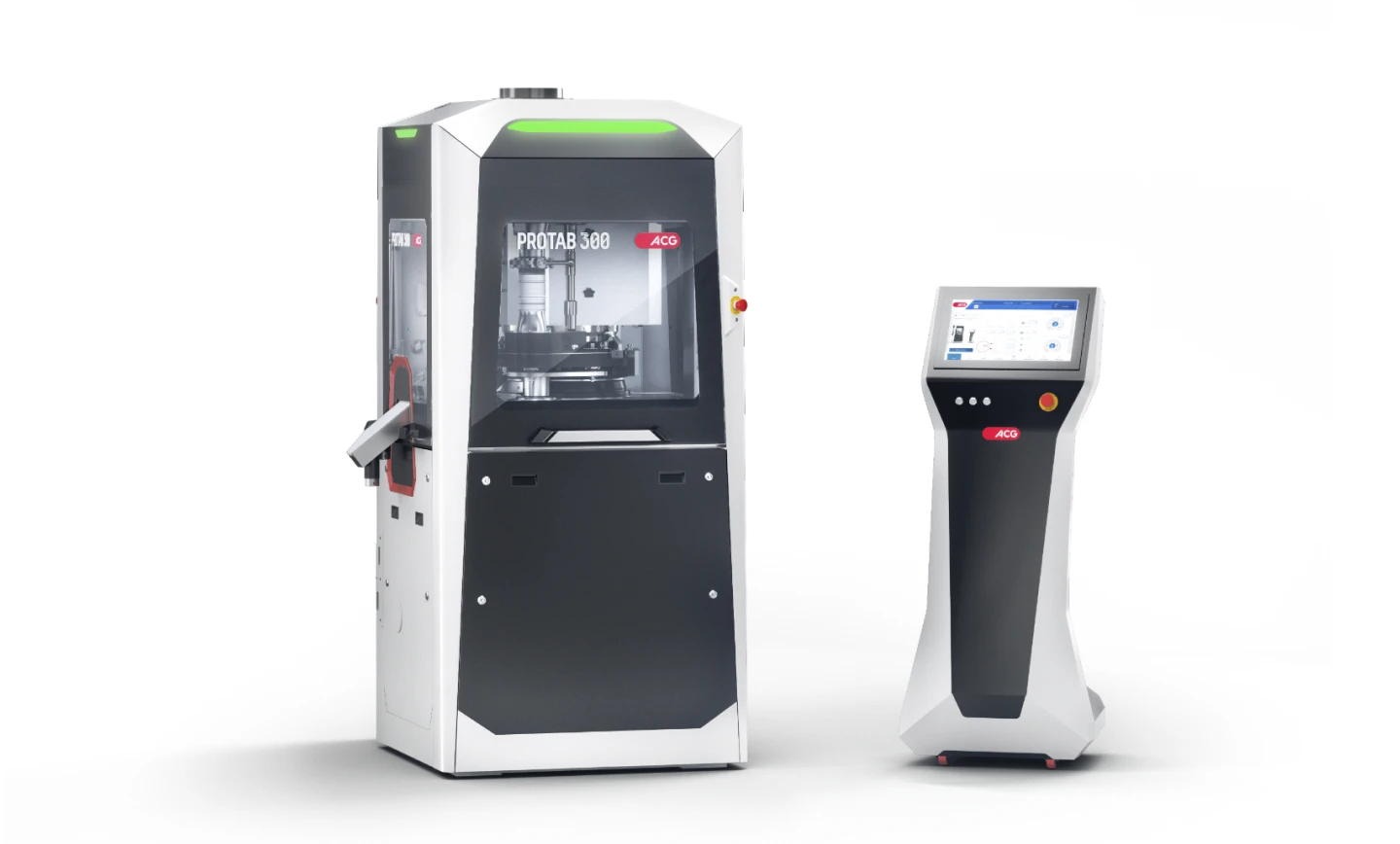

About the PROTAB™ 300

PROTAB™ 300 is a single rotary tablet press suitable for R&D, small and medium-batch production, making scalability far easier. With operator-friendliness front of mind, it’s loaded with state-of-the-art features that take automatic tablet-compression to another level. It helps increase output and secures greater production uptime, and makes routine tablet-compression processes far more intuitive and efficient, thanks to an upgraded user interface and interactive dashboard.

Applications

Compression of pharmaceutical and nutraceutical granules and MUPS into monolayer tablets

| Features | Benefits | |

|---|---|---|

An R&D turret with combinations for testing different types of formulation and tooling | Easily scalable from R&D batches to pilot, on the same machine | |

Available with specialised kits for multiple-unit particulate systems (MUPS) and challenging formulations that use ingredients (powder) which are abrasive, corrosive or have poor flow properties | Reduced segregation and crushing of pellets and powders means improved tablet uniformity and dependable dissolution profiles

The specialised kit deals far more effectively with abrasive ingredients | |

Interchangeable turrets | Flexibility of compressing various tablet sizes at varying speeds | |

Lightweight and toolless design of assemblies | Mechanical changeover in less than 30 minutes means greater efficiencies in production | |

InstAmend technology for faulty punch detection and rectification | Eliminates long process interruptions and reduces downtime | |

Precise single sorting, sampling and rejection of tablets at rated RPMs | Ensures accuracy and repeatability of the required specification criteria (weight, height, thickness) of the tablets being produced | |

Sophisticated feeder design | Leftover powder (<50g) reduces loss of valuable formulation |

Features & Benefits

An R&D turret with combinations for testing different types of formulation and tooling

Easily scalable from R&D batches to pilot, on the same machine

Available with specialised kits for multiple-unit particulate systems (MUPS) and challenging formulations that use ingredients (powder) which are abrasive, corrosive or have poor flow properties

Reduced segregation and crushing of pellets and powders means improved tablet uniformity and dependable dissolution profiles

The specialised kit deals far more effectively with abrasive ingredients

Interchangeable turrets

Flexibility of compressing various tablet sizes at varying speeds

Lightweight and toolless design of assemblies

Mechanical changeover in less than 30 minutes means greater efficiencies in production

InstAmend technology for faulty punch detection and rectification

Eliminates long process interruptions and reduces downtime

Precise single sorting, sampling and rejection of tablets at rated RPMs

Ensures accuracy and repeatability of the required specification criteria (weight, height, thickness) of the tablets being produced

Sophisticated feeder design

Leftover powder (<50g) reduces loss of valuable formulation

Technical specifications

| Punch type | D | B | BB | BBS |

| Punch stations | 21 | 27 | 34 | 36 |

| Output | 126,000 tablets/hr | 162,000 tablets/hr | 204,000 tablets/hr | 216,000 tablets/hr |

| Maximum tablet diameter | 25 mm | 16 mm | 13 mm | 11 mm |

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS