About the BP 450AD

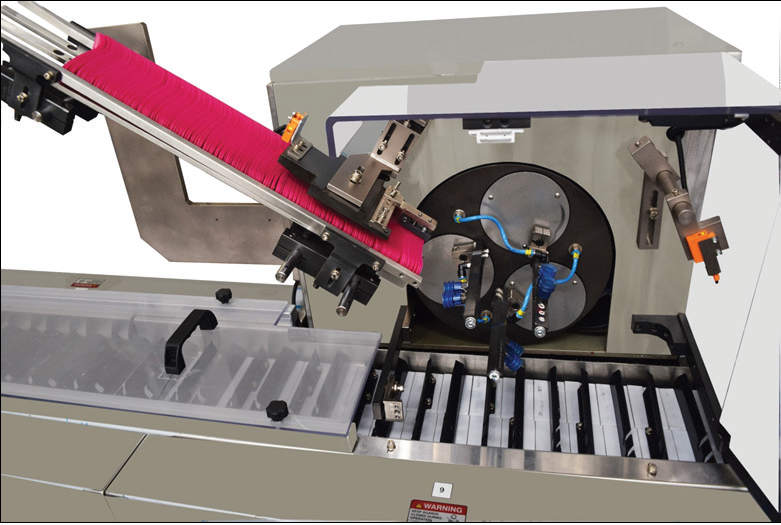

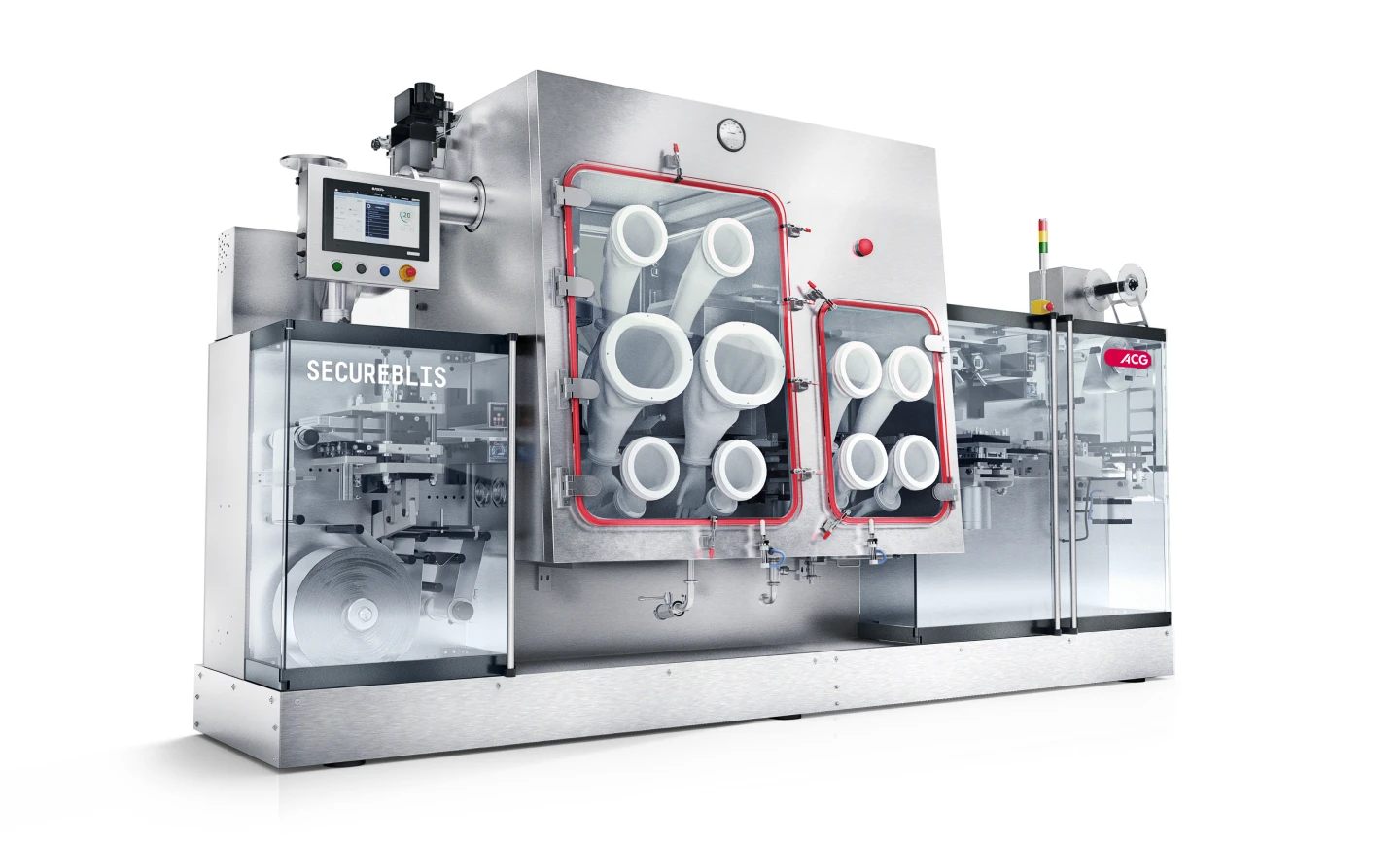

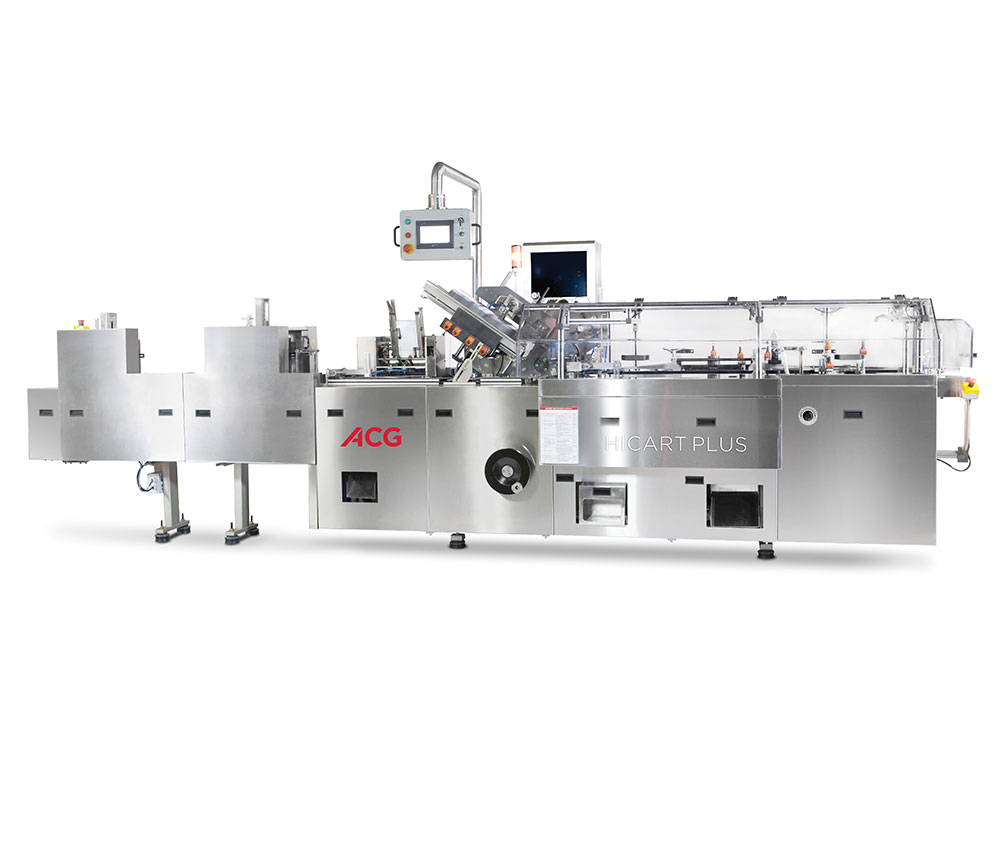

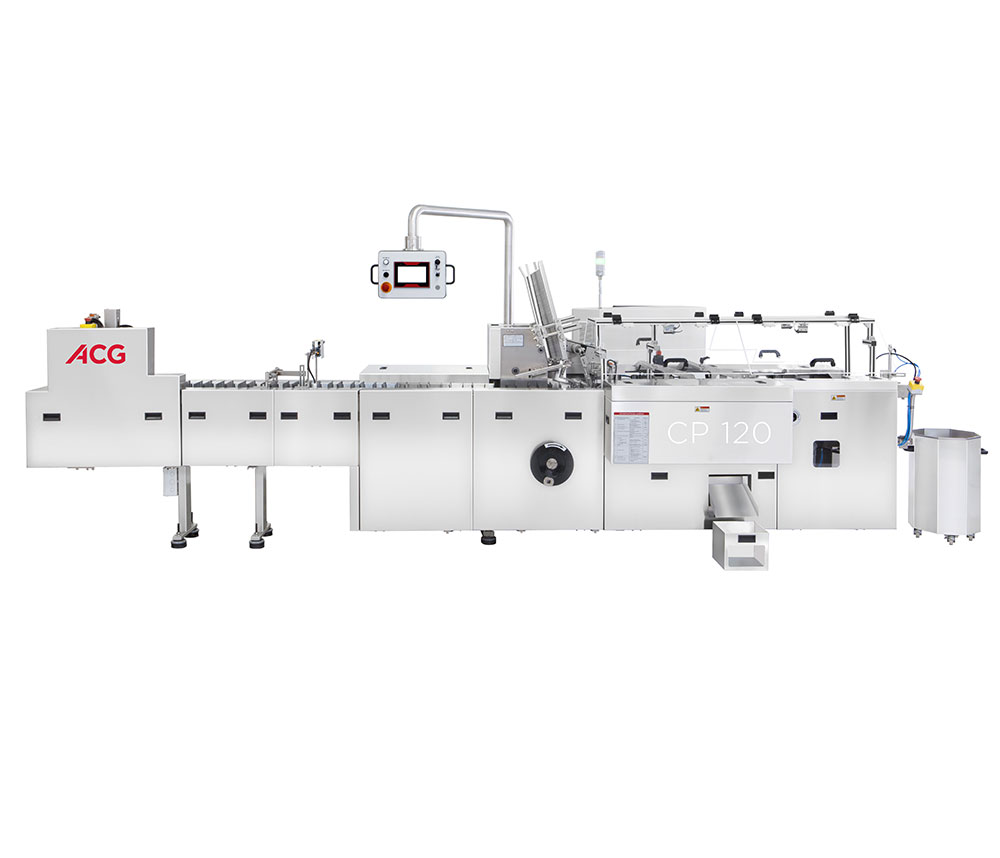

A deep-cavity blister packaging machine for ampoules, vials, pre-filled syringes, tubes, and combination packs of syringes and ampoules. ACG’s BP 450AD combines the principles of vacuum thermoforming with our proven single-drum continuous-motion technology, and ensures seamless and simple feeding and operation.

Applications

Blister packaging of solid dosage products and vials, ampoules and syringes

| Features | Benefits | |

|---|---|---|

A single drum for forming and sealing | Better blister quality, with fewer format parts | |

Forming up to a cavity depth of 28 mm | Simplified feeding, facilitating the formation of deep-cavity blisters | |

Print Registration and Control (PRC) enabled | Ensures appropriate print content on the final blister | |

Easy-fit punch-tool assembly | Faster, easier and safer changeover |

Features & Benefits

A single drum for forming and sealing

Better blister quality, with fewer format parts

Forming up to a cavity depth of 28 mm

Simplified feeding, facilitating the formation of deep-cavity blisters

Print Registration and Control (PRC) enabled

Ensures appropriate print content on the final blister

Easy-fit punch-tool assembly

Faster, easier and safer changeover

Technical specification

| Output | Up to 4.5 m/min (Thermoforming) |

| Forming depth | Up to 28 mm (Thermoforming) |

| Maximum blister size | 200 mm x 100 mm |

| Forming materials | PVC, PVC/PVdC, Triplex (PVC/PE/PVdC) |

| Lidding materials | Push-through foil, child-resistant foil, peelable (paper) |

You can’t have healthy people without a healthy planet.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS