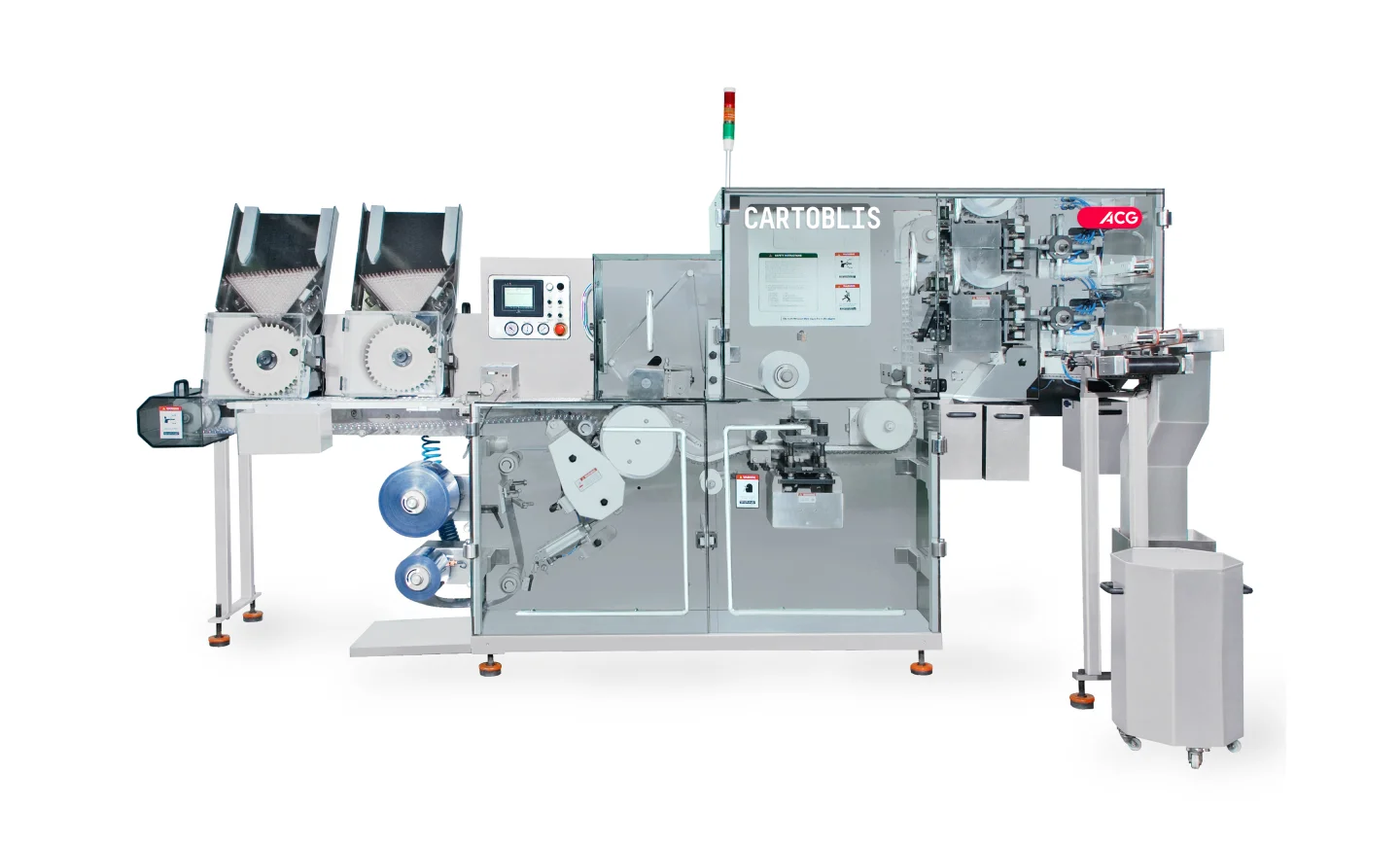

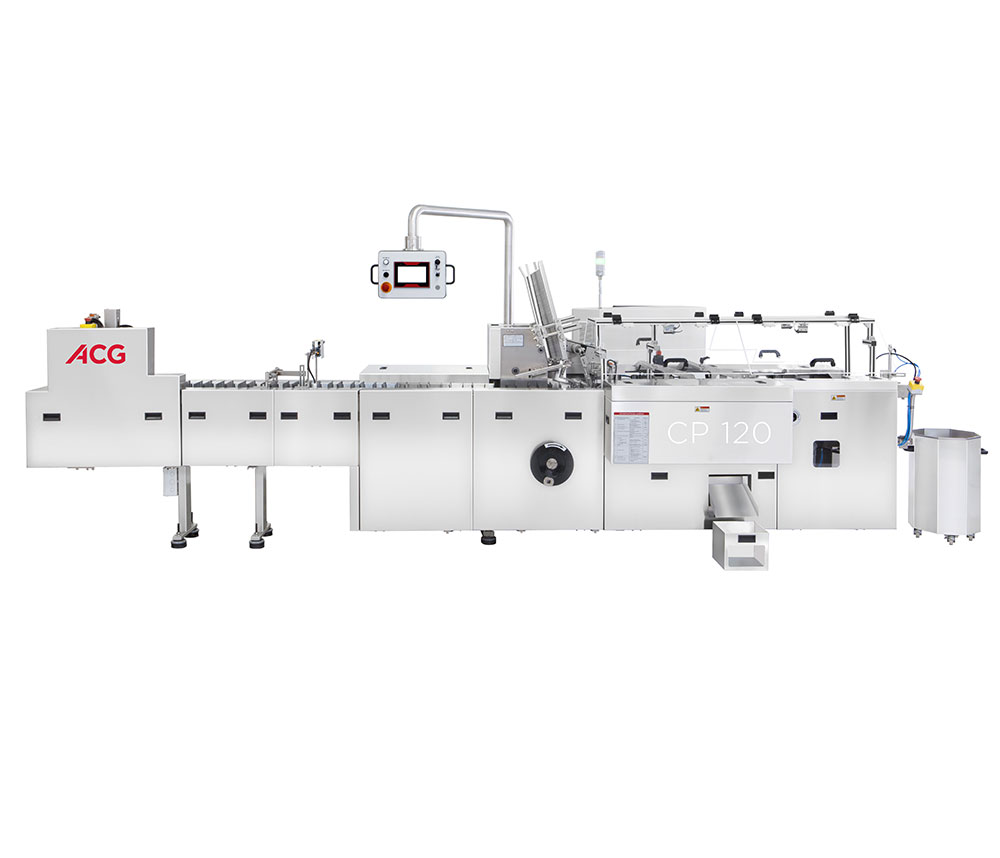

About the CARTOBLIS

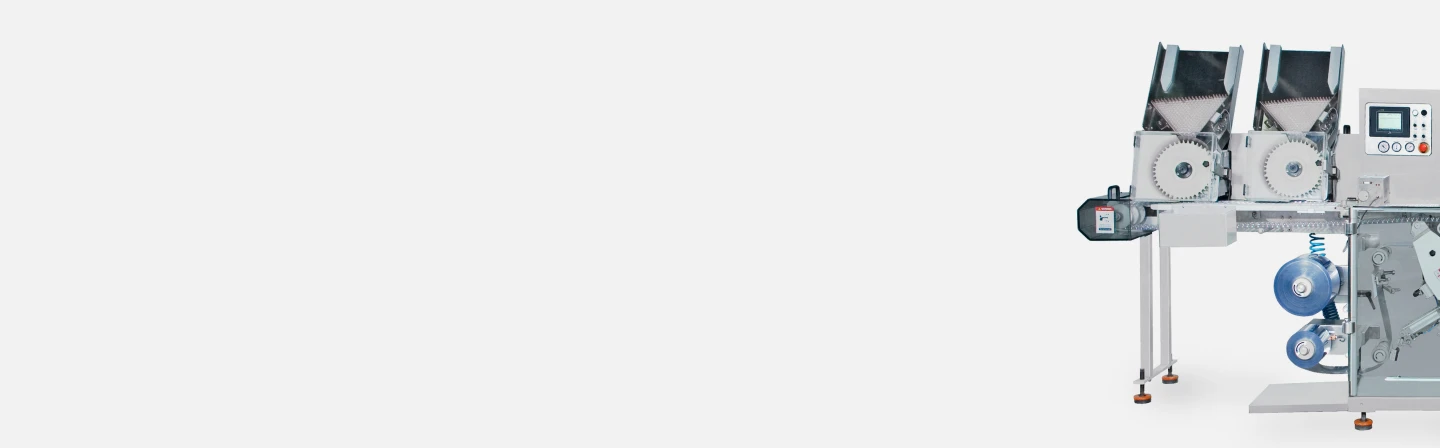

A cost-effective blister-packaging machine that integrates seamlessly with online cartoning in various layout configurations. Based on unique single-drum technology and advanced automation, CARTOBLIS offers high flexibility.

Applications

Blister packaging of solid dosage products and vials, ampoules and syringes

| Features | Benefits | |

|---|---|---|

Vacuum-based rotary thermoforming with unique single-drum technology | Better blister quality, using fewer format parts | |

Fast punching and blister pick-up | High output with better blister quality | |

Edge-to-edge punching | Reduces foil wastage in web travel direction | |

Integration with carton packaging machine | Provides continuous feed to any online cartoner, fully automating the blister-cartoning operation |

Features & Benefits

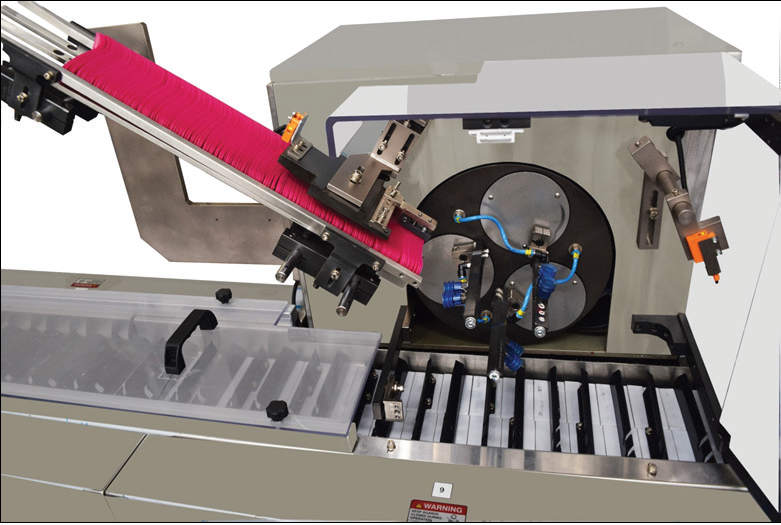

Vacuum-based rotary thermoforming with unique single-drum technology

Better blister quality, using fewer format parts

Fast punching and blister pick-up

High output with better blister quality

Edge-to-edge punching

Reduces foil wastage in web travel direction

Integration with carton packaging machine

Provides continuous feed to any online cartoner, fully automating the blister-cartoning operation

Technical specification

| Output | Up to 6.5 m/min (Thermoforming) |

| Forming depth | Up to 12 mm (Thermoforming) |

| Format area | 200 mm x 100 mm |

| Forming materials | PVC, PVC/PVdC, Triplex (PVC/PE/PVdC) |

| Lidding materials | Push-through foil, child-resistant foil, peelable (paper) |

Always getting better at helping make people better.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS