About the CODE series

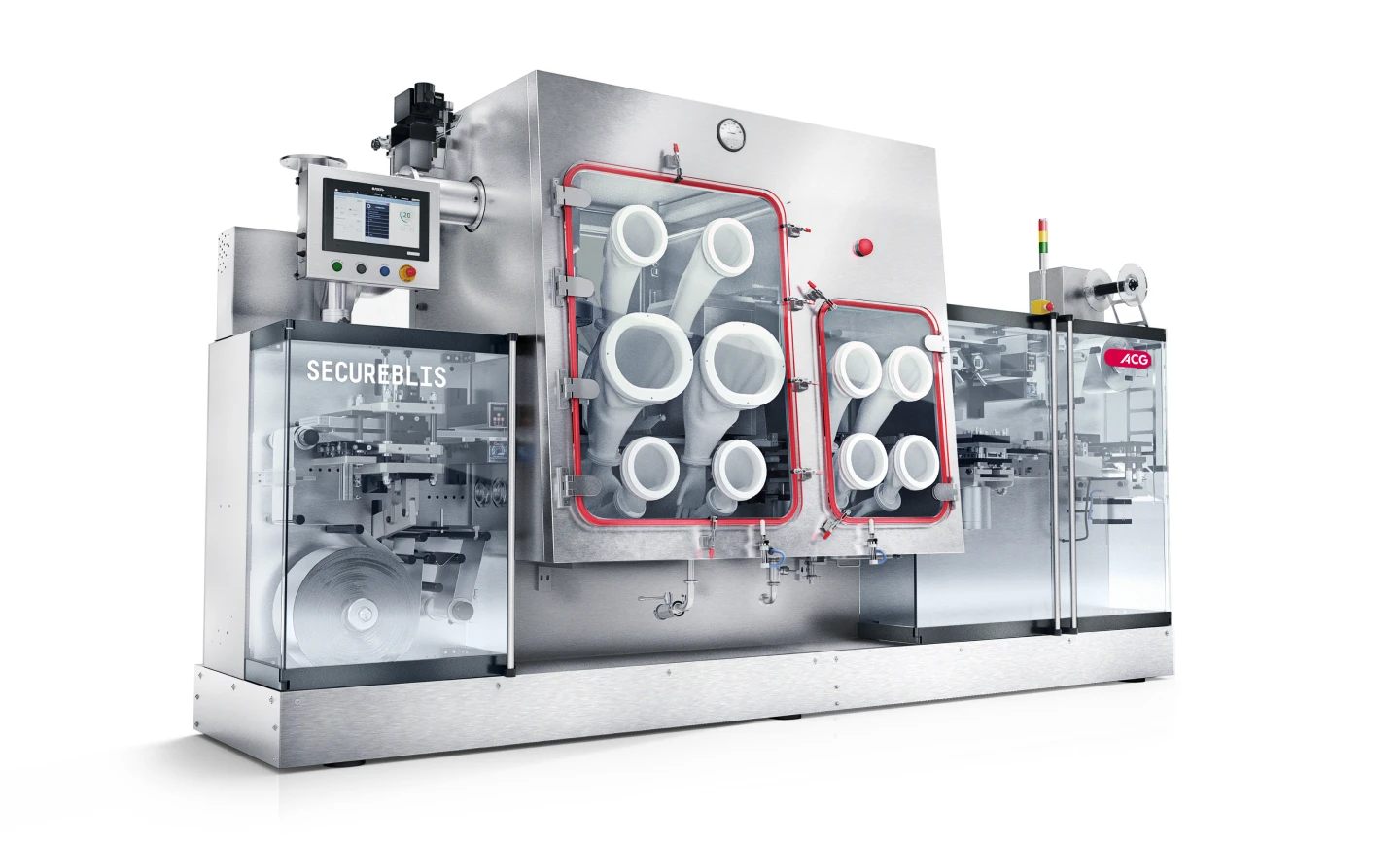

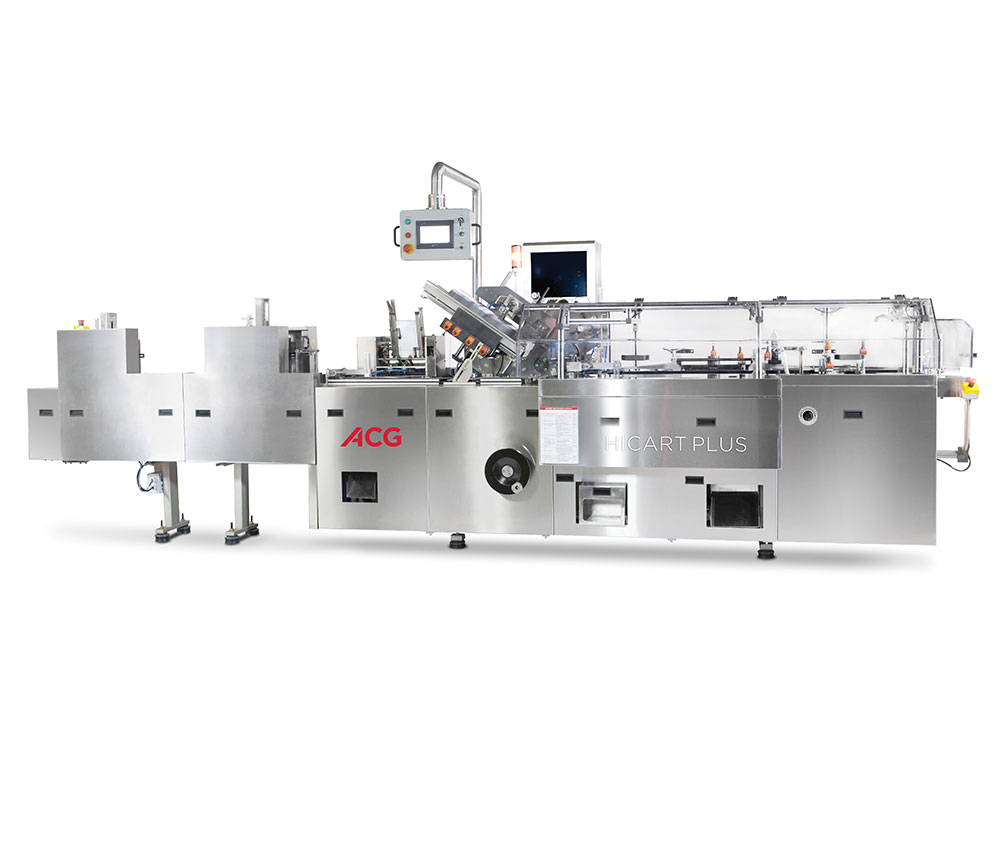

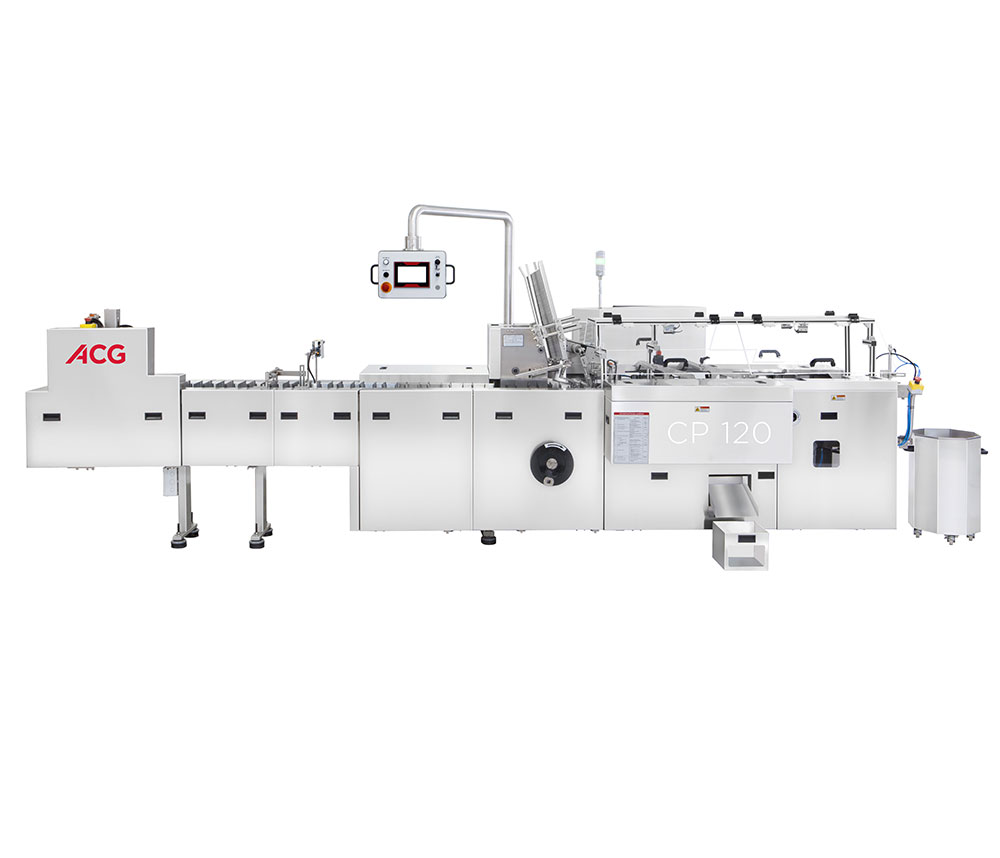

Enabling many innovations for the pharmaceutical industry, ACG’s customised oral dosage encapsulation (CODE) series comprises custom-made attachments for special encapsulation needs. Retrofittable on encapsulation machines developed and manufactured by ACG, the CODE series enables the filling of capsules with a wide range of combinations – such as granules, pellets, powders, mini- and micro-tablets, capsules and soft gels.

Applications

Solid filling

Powder, pellets, tablets, micro-tablets, capsules and combinations thereof

Liquid filling

Liquids and pellets, tablets, micro-tablets, capsules, and their combinations in liquid

| Features | Benefits | |

|---|---|---|

Adept at filling capsules with powders, tablets, capsules, pellets, liquids – and combinations thereof | Achieve highly versatile dosage forms

Possibility of combining more than one drug substance and release profile in a single capsule | |

Combinations of up to four different product types | Create innovative drug products that can facilitate patients’ compliance with treatment regimes | |

Retrofittable to all encapsulation machines across R&D, pilot and production scales | Enhances the versatility of the encapsulation machine without additional investment | |

Fully customisable to product weight and dimensions | Every attachment is suited to the needs of the application as required | |

Vision-based inspection systems | For improved quality capsules with higher accuracy in weight | |

Minimal change parts required | Higher value for money on investment, and cost-effective in the long term |

Features & Benefits

Adept at filling capsules with powders, tablets, capsules, pellets, liquids – and combinations thereof

Achieve highly versatile dosage forms

Possibility of combining more than one drug substance and release profile in a single capsule

Combinations of up to four different product types

Create innovative drug products that can facilitate patients’ compliance with treatment regimes

Retrofittable to all encapsulation machines across R&D, pilot and production scales

Enhances the versatility of the encapsulation machine without additional investment

Fully customisable to product weight and dimensions

Every attachment is suited to the needs of the application as required

Vision-based inspection systems

For improved quality capsules with higher accuracy in weight

Minimal change parts required

Higher value for money on investment, and cost-effective in the long term

Possibilities of filling capsules with different combinations using CODE

| Encapsulation machines | Fill type | ||

Powder | Tablets/pellets/ micro-tablets/ capsules | Liquid | |

| AF series |

|

|

|

FLUIDOCAP F70 |

|

|

|

SECUREFILL series |

|

|

|

| ZRO series |

|

|

|

| SA 9 |

|

|

|

Always getting better at helping make people better.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS