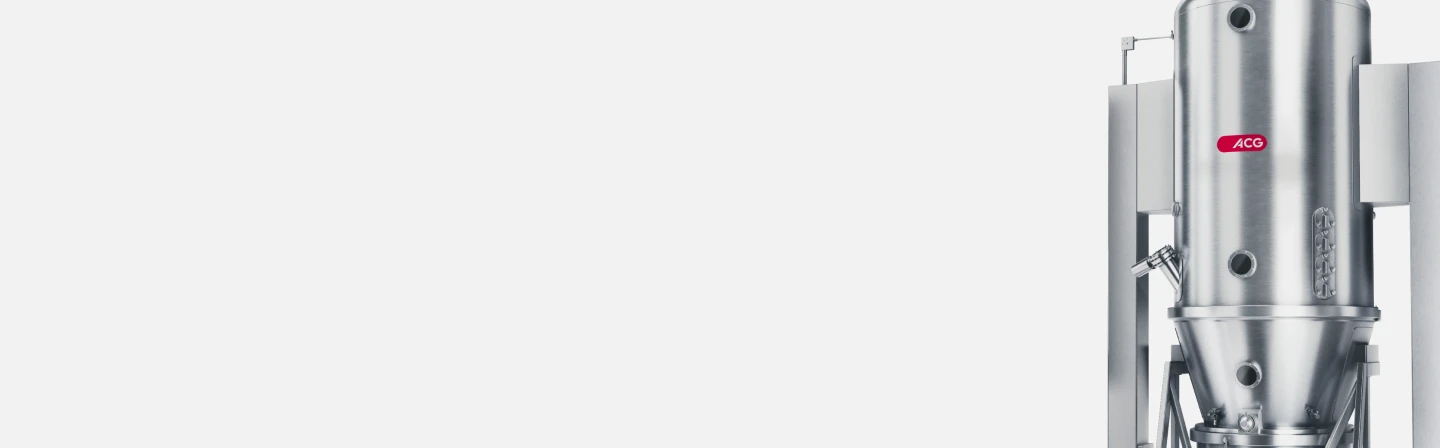

About the FBE 500 X•ONE

The FBE X•ONE series is our most advanced range of fluid-bed systems. Developed at our Design Centre in Mülheim, Germany, it sets a new benchmark for performance, handling and operational safety. Offering excellent top-spray granulation and drying, it has already optimised the processing of over 1,800 formulations.

FBE 500 X•ONE is suitable for granulation and drying of batches up to 500 l.

Applications

Top-spray granulation, wet-mass drying, hot-melt granulation

| Features | Benefits | |

|---|---|---|

A 12-bar pressure-shock-resistant system, featuring the MOST™ (Maximum Operator Safety Technology) concept approved by FSA from Germany, and compliant with ATEX (Directive 2014/34/EU) | No mechanical deformation caused by pressure-shock

Production can be resumed with the machine in the shortest possible time

Far safer for the environment, thanks to a non-vented, fully contained design | |

Unique C-flanges | Prevents the transfer of the explosion pressure beyond the machine | |

X•ONE inflatable seals | Safety at low pressure (as low as low as 4.5 bar) | |

QASV (Quick Action Stop Valves) | Ensures explosion is contained within 20 milliseconds of detection | |

ACG’s exclusive X•ONE command process control system | Compliant with ATEX (Directive 2014/34/EU), GAMP 5 and 21 CFR Part 11, this advanced technology allows intuitive, secure monitoring and control | |

Customised charging, discharging and WIP (wash-in-place) systems – available in standalone and granulation-train configurations | Makes processing of granules highly efficient, ensures safety, and reduces changeover times |

Features & Benefits

A 12-bar pressure-shock-resistant system, featuring the MOST™ (Maximum Operator Safety Technology) concept approved by FSA from Germany, and compliant with ATEX (Directive 2014/34/EU)

No mechanical deformation caused by pressure-shock

Production can be resumed with the machine in the shortest possible time

Far safer for the environment, thanks to a non-vented, fully contained design

Unique C-flanges

Prevents the transfer of the explosion pressure beyond the machine

X•ONE inflatable seals

Safety at low pressure (as low as low as 4.5 bar)

QASV (Quick Action Stop Valves)

Ensures explosion is contained within 20 milliseconds of detection

ACG’s exclusive X•ONE command process control system

Compliant with ATEX (Directive 2014/34/EU), GAMP 5 and 21 CFR Part 11, this advanced technology allows intuitive, secure monitoring and control

Customised charging, discharging and WIP (wash-in-place) systems – available in standalone and granulation-train configurations

Makes processing of granules highly efficient, ensures safety, and reduces changeover times

Technical specifications

| Working volume* | Min | 135 l |

| Max | 608 l |

*Dependent on bulk density

Also Available In

|

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS