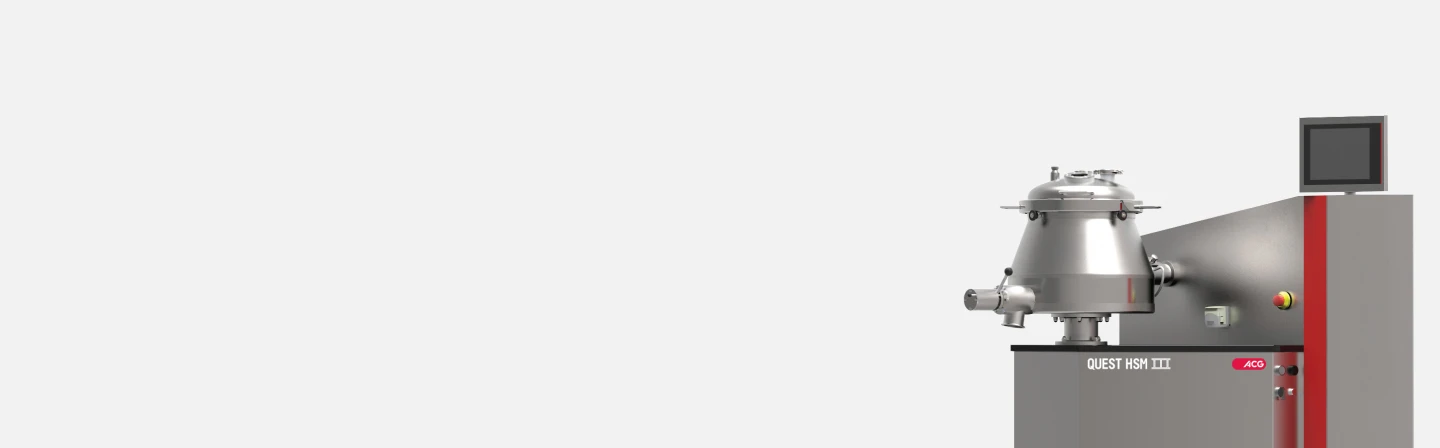

About the QUEST HSM III

An advanced series of high-shear mixer granulators that ensure faster processing and narrow particle-size distribution, while achieving content uniformity in the dry mix. The system is equipped with ACG's process control system and features the unique MOST™ (Maximum Operator Safety Technology) concept.

QUEST HSM III supports R&D at lab and pilot scale, and is designed to help with cGMP compliance. Its standalone plug-and-play design enables swift and effortless set up.

Applications

Mixing, hot-melt granulation and wet granulation

| Features | Benefits | |

|---|---|---|

A 12-bar pressure shock-resistant system featuring the MOST™ (Maximum Operator Safety Technology) concept approved by FSA in Germany and compliant with ATEX (Directive 2014/34/EU) | No mechanical deformation caused in case of a pressure-shock event

Production can be resumed in the shortest possible time

A far safer working environment, thanks to a non-vented, fully contained design | |

ACG’s exclusive process control system | Compliant with ATEX, GAMP 5 and 21 CFR Part 11, this advanced technology allows intuitive, secure monitoring and control | |

Designed with Z-shaped impeller blades | Optimum flow of material in and out of the shear zone, minimising accumulation or sticking on the product bowl | |

Standalone mobile plug-and-play system | Use wherever it’s needed in the lab, quickly and easily | |

Multi-blade straight chopper | Breaks down lumps formed during granule formation, avoids ‘dead zones’, and achieves uniform binder distribution | |

Interchangeable bowls (15 l, 30 l, and 65 l) | Allows fully flexible batch sizes |

Features & Benefits

A 12-bar pressure shock-resistant system featuring the MOST™ (Maximum Operator Safety Technology) concept approved by FSA in Germany and compliant with ATEX (Directive 2014/34/EU)

No mechanical deformation caused in case of a pressure-shock event

Production can be resumed in the shortest possible time

A far safer working environment, thanks to a non-vented, fully contained design

ACG’s exclusive process control system

Compliant with ATEX, GAMP 5 and 21 CFR Part 11, this advanced technology allows intuitive, secure monitoring and control

Designed with Z-shaped impeller blades

Optimum flow of material in and out of the shear zone, minimising accumulation or sticking on the product bowl

Standalone mobile plug-and-play system

Use wherever it’s needed in the lab, quickly and easily

Multi-blade straight chopper

Breaks down lumps formed during granule formation, avoids ‘dead zones’, and achieves uniform binder distribution

Interchangeable bowls (15 l, 30 l, and 65 l)

Allows fully flexible batch sizes

Technical specifications

| Bowl size | 15 l | 30 l | 65 l | |

| Working volume* | Min | 4.5 l | 9 l | 19.5 l |

| Max | 9 l | 18 l | 39 l |

*Dependent on bulk density

Also Available In

|

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS