About the QUALISHIELD CV50

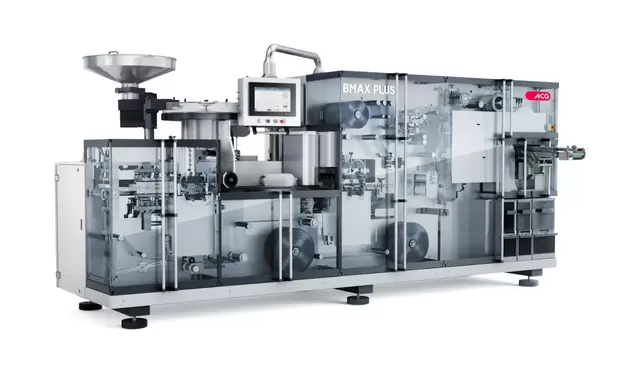

The QUALISHIELD CV series is a high-speed, high-resolution, multi-colour, camera-based solution for inspection of a variety of data, including barcodes, pharmacodes, 2D codes, batch details, and much more – on inspection media such as cartons, labels, leaflets, foils, tubes, and many others. You can install it on any carton- or blister-packing machine, and it’s retrofittable to a wide range of bottling, cartoning and manual packaging lines. The CV series can be integrated with various types of cameras, based on different needs.

QUALISHIELD CV50 is an online camera-based inspection system you can mount on any labelling, cartoning or blister-packaging machine. It accurately and reliably captures details such as batch and expiry, 1D barcodes, 2D datamatrix codes, pharmacodes – on inspection media including cartons, labels, foils, leaflets, tubes, and many others.

Applications

Pharmacode, barcode and OCR/OCV inspection on carton, leaflet, and booklet

| Features | Benefits | |

|---|---|---|

Inspects contents of cartons, labels, foils, leaflets and tubes using a modular software architecture | One hardware and software solution for multiple uses in a single setup | |

Supports printing in continuous inkjet, thermal inkjet, hot stamping and thermal transfer overprinters (TTOs) | Compatibility with a wide range of industrial printers | |

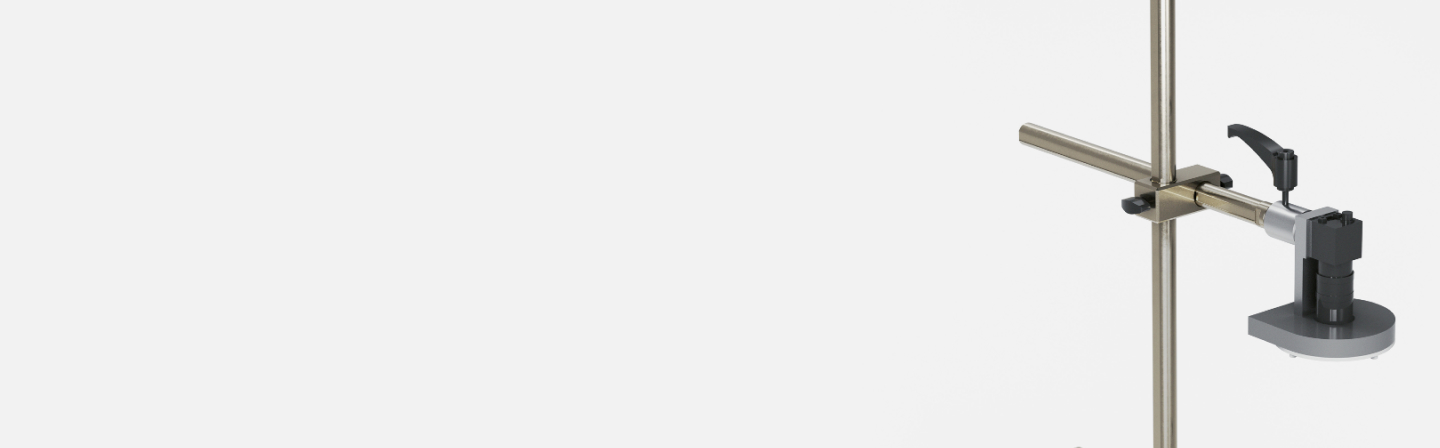

A plug-and-play installation that supports all types of PLC rejection mechanism protocols | Accurately and reliably captures details on labels such as batch and expiry, 1D barcodes, 2D datamatrix codes, pharmacodes | |

Fast and easy plug-and-play installation | Can be integrated with continuous or intermittent machines |

Features & Benefits

Inspects contents of cartons, labels, foils, leaflets and tubes using a modular software architecture

One hardware and software solution for multiple uses in a single setup

Supports printing in continuous inkjet, thermal inkjet, hot stamping and thermal transfer overprinters (TTOs)

Compatibility with a wide range of industrial printers

A plug-and-play installation that supports all types of PLC rejection mechanism protocols

Accurately and reliably captures details on labels such as batch and expiry, 1D barcodes, 2D datamatrix codes, pharmacodes

Fast and easy plug-and-play installation

Can be integrated with continuous or intermittent machines

Technical specifications

| FOV (Field of view) | 60mm x 40mm |

| Number of cameras | 1 |

| Products that can be inspected | Carton, leaflet, label, vial |

| Maximum speed* | 400 products/min |

* Speed can vary according to the number of camera configurations, image saves, camera configurations (one or more), and product size. | |

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS