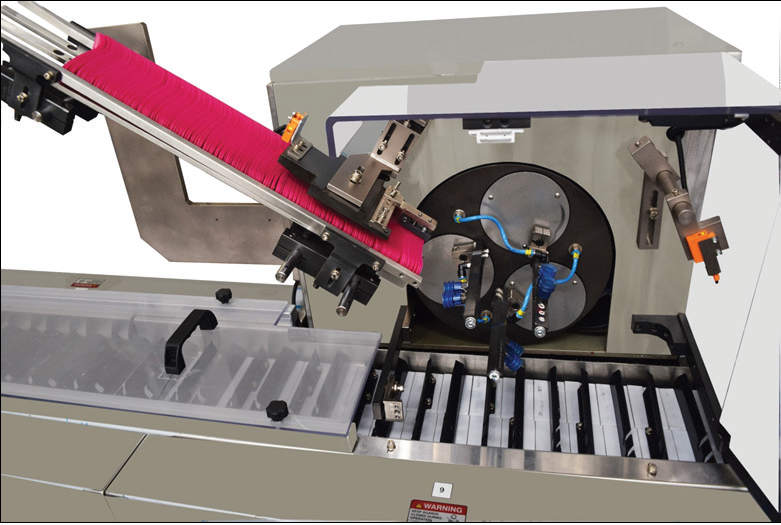

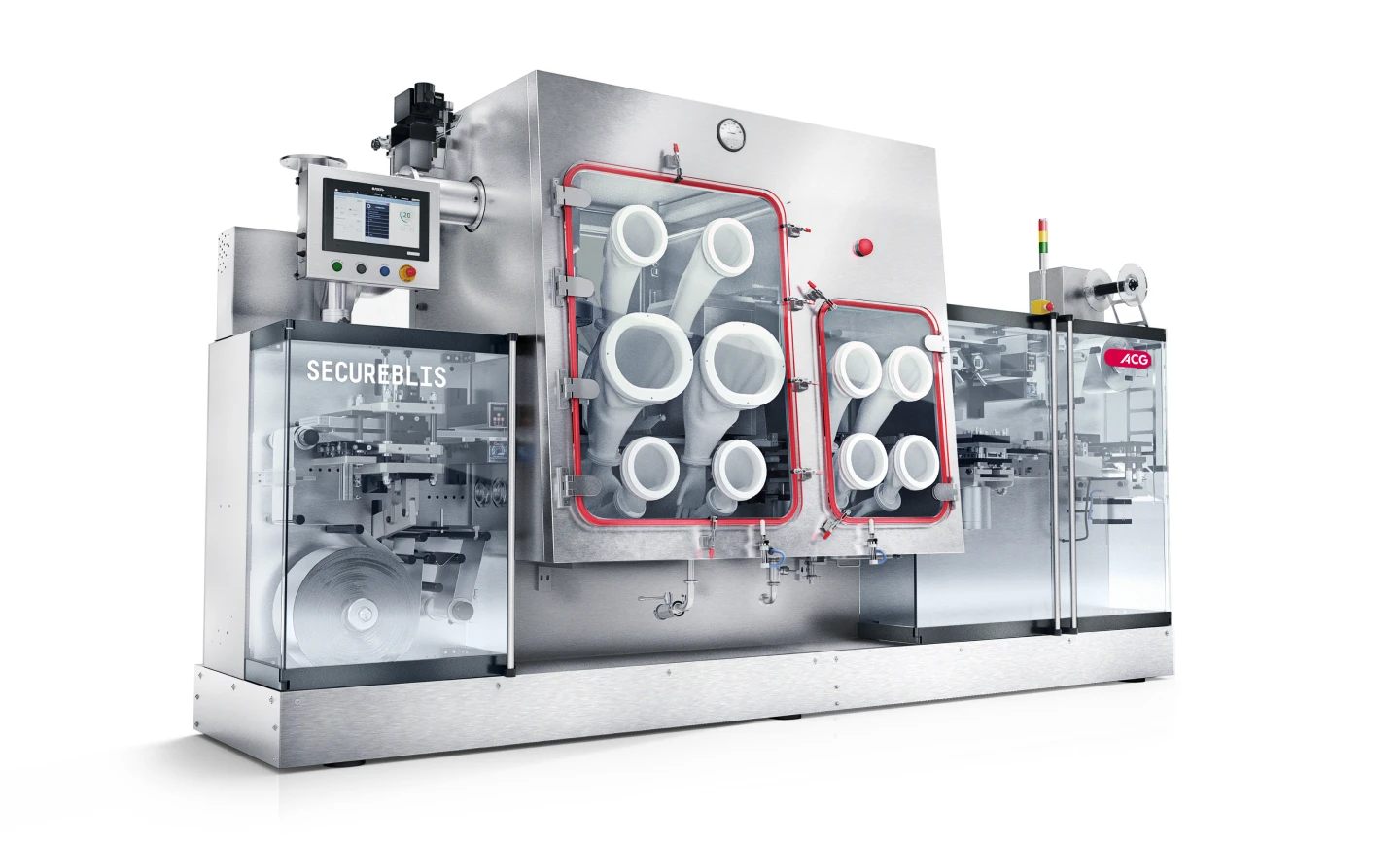

About the MINIBLIS

ACG’s MINIBLIS is a compact, fully versatile flat-forming, flat-sealing intermittent-motion machine for all forms of blister packs in short-run and small production batches. It supports the production of all configurations of blisters, including thermoforming films and cold-form foils.

Applications

Blister packaging of solid dosage products such as tablets, hard capsules and soft gelatin capsules

| Features | Benefits | |

|---|---|---|

Nitrogen-purging capability | Facilitates handling of moisture-sensitive and hygroscopic products | |

Handles thermoform and cold-form applications | Versatile and adaptable to a wide range of R&D set-ups | |

Compact footprint | Higher output per square metre | |

Low power consumption | Low total-cost-of-ownership | |

Interactive human-machine interface (HMI) and IPC | User-friendly controls | |

Can be integrated with all visual inspection machines | Ensures high-quality blister packs |

Features & Benefits

Nitrogen-purging capability

Facilitates handling of moisture-sensitive and hygroscopic products

Handles thermoform and cold-form applications

Versatile and adaptable to a wide range of R&D set-ups

Compact footprint

Higher output per square metre

Low power consumption

Low total-cost-of-ownership

Interactive human-machine interface (HMI) and IPC

User-friendly controls

Can be integrated with all visual inspection machines

Ensures high-quality blister packs

Technical specification

| Forming cycle | Thermoforming | Up to 25 cycles/min |

| Cold-forming | Up to 20 cycles/min | |

| Forming depth | Thermoforming | Up to 12 mm |

| Cold-forming | Up to 9 mm | |

| Maximum forming area | 156 mm x 96 mm | |

| Forming materials | PVC, PVC/PVdC, Triplex (PVC/PE/PVdC), cold-form foil (Alu) | |

| Lidding materials | Push-through foil, child-resistant foil, peelable (paper) | |

Wherever in the world there's a medicine cabinet, we're almost certainly somewhere inside it.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS