Should you bottle it up or blister it?

Product protection and shelf life

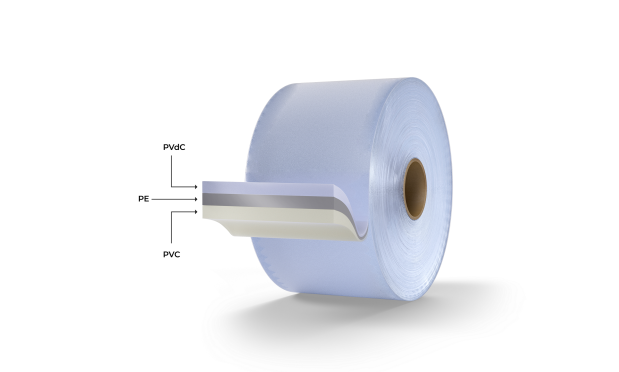

One of the primary functions of pharmaceutical packaging is to protect the product from potential ambient degradants such as moisture, oxygen, and light. Blister packs are designed with materials like PVC, PVDC, and aluminium, which offer excellent barriers against moisture and oxygen. These materials can be customised to provide varying levels of protection, depending on the drug’s sensitivity to environmental conditions. In contrast, HDPE bottles may expose all its filled contents to environmental conditions as soon as the container is opened. This exposure can degrade sensitive active ingredients more rapidly, potentially reducing the medication’s efficacy before it’s fully consumed. By comparison, blister packaging ensures that each unit remains sealed until it’s accessed by the patient, maintaining the integrity of each dose.

Some drug substances are sensitive to light, and any prolonged exposure of products containing such drugs may adversely affect their stability. While bottles are often opaque, they do not provide the same degree of light protection as blister packs, especially when compared to aluminium-based packaging materials. This ensures that each dose remains protected from light until it is administered.

Enhanced patient compliance and safety

Blister packaging offers significant advantages in terms of promoting patient compliance, which is critical for the effectiveness of any medication regimen. Blister packs enable unit-dose dispensing, meaning each dose is packaged separately. This allows patients to easily track their consumption, reducing the risk of missed or double doses. Many blister packs also include printed information about the days of the week, making it even easier for patients to remember if they have taken their medication. For high-risk patient populations, such as the elderly, unit-dose packaging can be particularly beneficial in reducing medication errors. Bottles, on the other hand, require patients to remember the correct dosage and track their usage, which can lead to confusion and unintentional non-adherence.

Child-resistant and senior-friendly features

While both blister packs and bottles can incorporate child-resistant features, studies indicate that blister packaging is 65%1 more effective than child-resistant bottles in preventing child access to medication. Blister packaging can also provide a more effective balance between child resistance and senior-friendly design. In cases where senior-friendly features are necessary, blister packs can incorporate peel-push designs as well to make it easy for older adults to manage, which may not be as intuitive in traditional bottle packaging.

Enhanced labelling and branding

The individual cavities in blister packaging can be labelled or printed with branding elements, making it easier to identify the product and dosage information at a glance. This can enhance the patient adherence by providing a clear, visually distinctive product that is easy to identify and use. Additionally, blister packs allow for the inclusion of comprehensive product information directly on the packaging, reducing the need for additional labelling.

Enhanced security and counterfeit prevention

Blister packaging offers advantages in terms of product security, reducing the risk of tampering and counterfeiting, both of which are serious concerns in the pharmaceutical industry.

Blister packs provide an inherent tamper-evident design, as each cavity is sealed individually. This makes it easy to detect if a dose has been compromised, as any attempt to remove a tablet or capsule would leave visible evidence. With bottles, tamper-evidence is typically provided by an external seal, which is easier to bypass without direct product indication.

Cost benefits

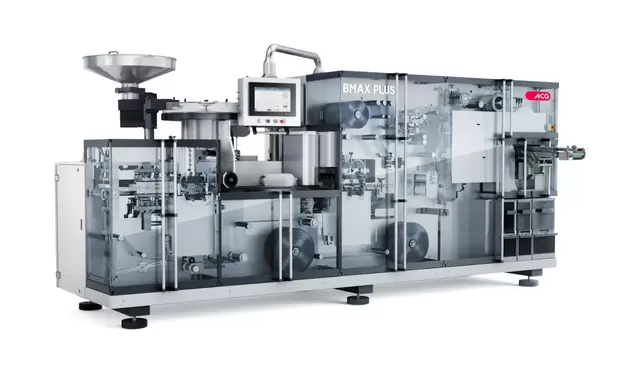

While the initial costs for blister packaging equipment can be high, the materials used in blister packs are often cheaper per unit than bottles, especially for high-volume production.

Blister packaging stands out in logistics due to its lightweight and compact design, which significantly lowers shipping costs. Unlike bulky HDPE bottles, blister packs can fit more units per shipment, optimising logistics expenses and reducing the overall cost associated with storage and transport. This efficiency directly impacts the total cost of ownership, as lower shipping volumes reduce fuel consumption, contributing to cost savings and sustainability. The compact nature of blister packs is particularly advantageous for high-volume distribution, as pharmaceutical companies can ship more products in the same space, enhancing operational efficiency.

Moreover, the compact design of blister packaging also provides significant advantages in retail environments, where space optimisation directly affects sales. Blister packs take up less shelf space than HDPE bottles, enabling retailers to display and store a broader variety of products within the same area.

Lower healthcare costs

The compliance and safety benefits of blister packaging can also contribute to lower healthcare costs in the long term. Improved patient compliance leads to better health outcomes, reducing the burden on healthcare systems. When patients take their medication correctly, the incidence of adverse events, hospital readmissions, and treatment failures can decrease, generating broader cost savings. Additionally, the tamper-evidence and anti-counterfeiting features of blister packaging help ensure that only authentic, uncontaminated products reach patients, reducing liability and potential costs associated with counterfeit products.

Conclusion

When evaluating packaging for pharmaceutical oral solids, blister packaging offers clear advantages over bottles, particularly when considering Total Cost of Ownership. Blister packaging ensures enhanced product protection, better patient compliance, and a higher degree of safety against tampering and counterfeiting. Additionally, blister packaging allows for reduced manufacturing waste, streamlined inventory management, and lower transportation costs, all of which contribute to a lower TCO. Given these advantages, blister packaging is not only an effective packaging choice but also a cost-efficient, patient-friendly solution that aligns with the quality and regulatory demands of the pharmaceutical industry.

- Ward Smith. Blisters vs. Bottles: Examining Prescription Packaging. Tablets & Capsules; Volume 21 Issue, March/April 2023. https://www.tabletscapsules.com/3641-Technical-Articles/594889-Blisters-vs-Bottles-Examining-Prescription-Packaging/

Go Back

Go Back