About the FBE 250C

Our versatile FBC expands your process efficiency exponentially. With your need for flexible operations in mind, we designed our combo series to feature top-spray and Wurster coating technology in one innovative machine. It’s a proven boost for the pharmaceutical and nutraceutical industries.

Whether it’s for drying, top-spray granulation, Wurster coating, rotor-based drug layering or tangential spray processes, the FBE 250C does it all – for batches up to 250 l.

Applications

Top-spray granulation, wet-mass drying, hot-melt granulation, tangential spray granulation, Wurster coating

| Features | Benefits | |

|---|---|---|

Precisely calculated and tested vent | Ensures operator and equipment safety in the event of pressure shock | |

The state-of-the-art twin-chamber filter bag shaking system | Helps achieve continuous fluidisation, via the largest possible filtration area

Meanwhile, it consumes far less compressed air compared with blowback filter systems

It’s also easier to handle and achieves better cleaning results | |

Product container with multiple air-distribution plates | Choose the air distribution that best suits your product | |

Customised charging, discharging and wash-in-place (WIP) systems available in standalone and granulation-train configurations | Efficient formulation processing, and easy washing |

Features & Benefits

Precisely calculated and tested vent

Ensures operator and equipment safety in the event of pressure shock

The state-of-the-art twin-chamber filter bag shaking system

Helps achieve continuous fluidisation, via the largest possible filtration area

Meanwhile, it consumes far less compressed air compared with blowback filter systems

It’s also easier to handle and achieves better cleaning results

Product container with multiple air-distribution plates

Choose the air distribution that best suits your product

Customised charging, discharging and wash-in-place (WIP) systems available in standalone and granulation-train configurations

Efficient formulation processing, and easy washing

Technical specifications

Working volume* | Top-spray granulation | Wurster coating | |

| Min | 70 l | 23 l | |

| Max | 344 l | 170 l |

*Dependent on bulk density

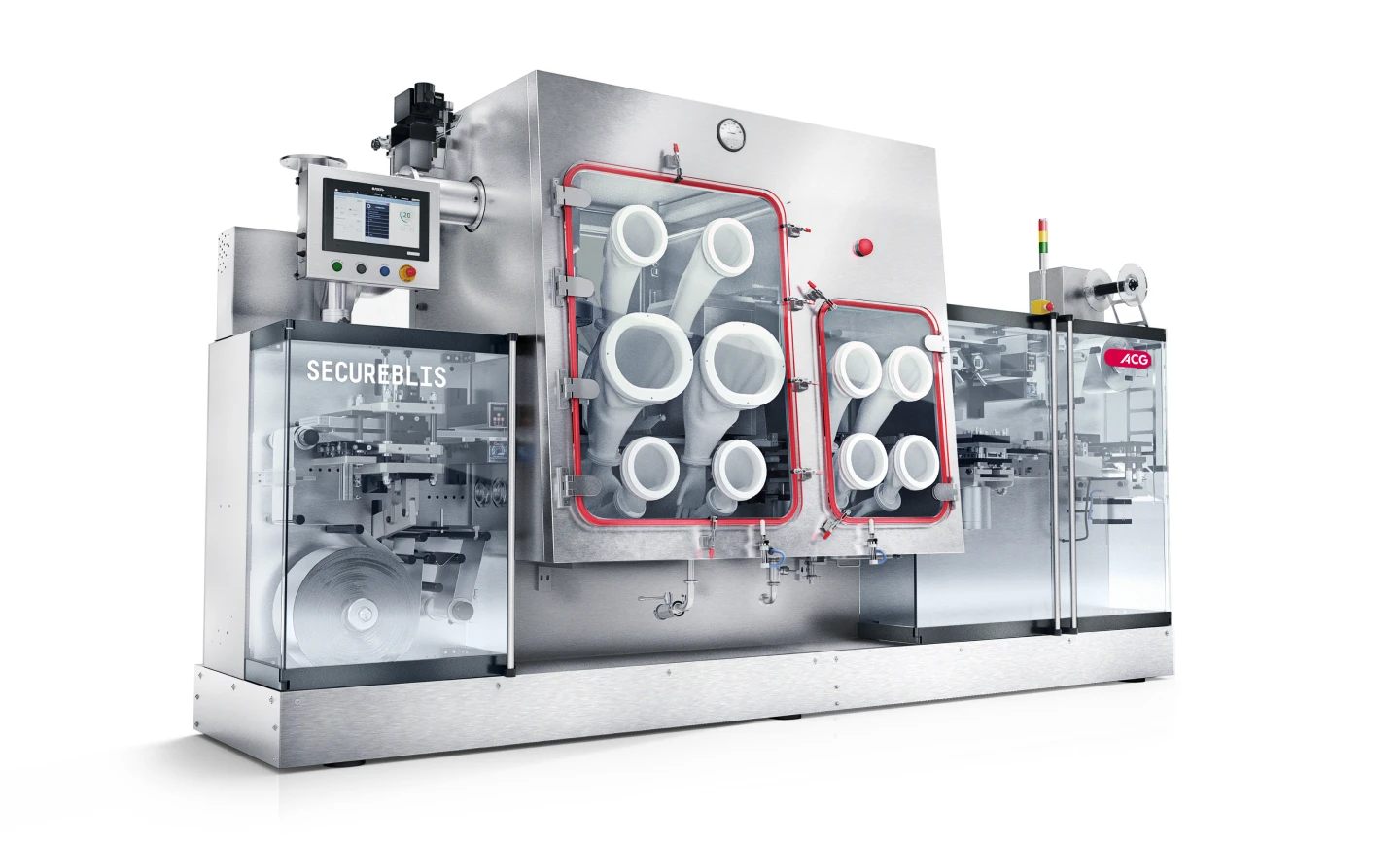

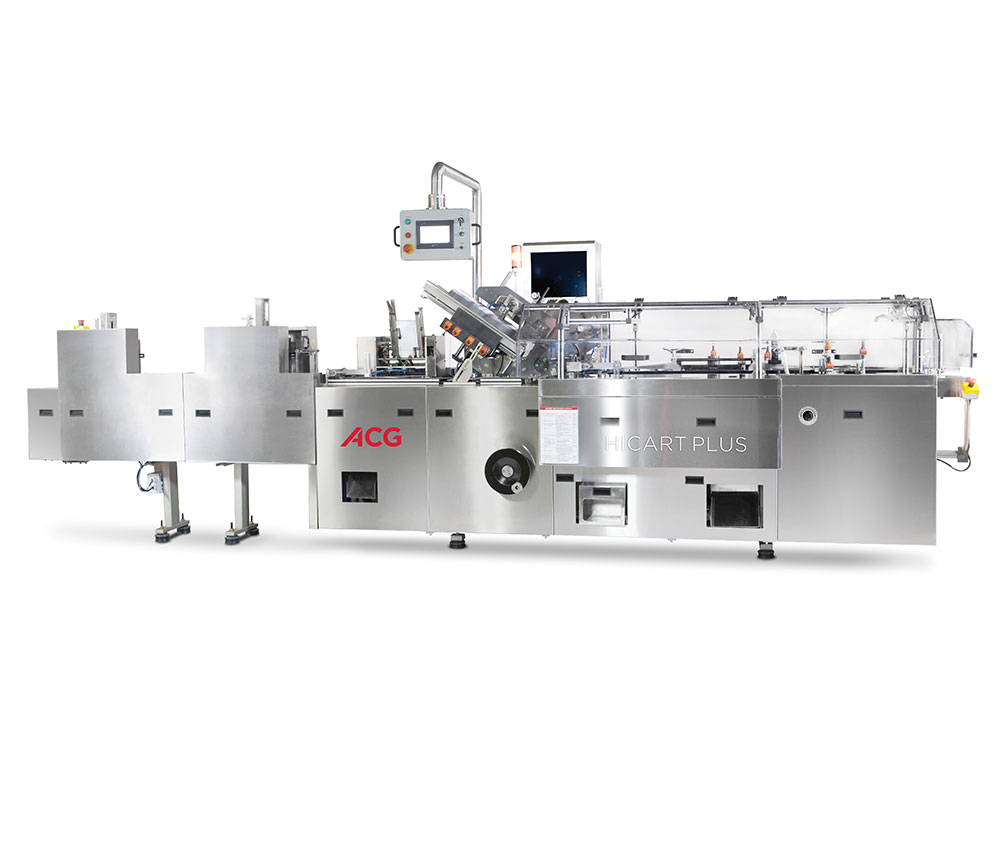

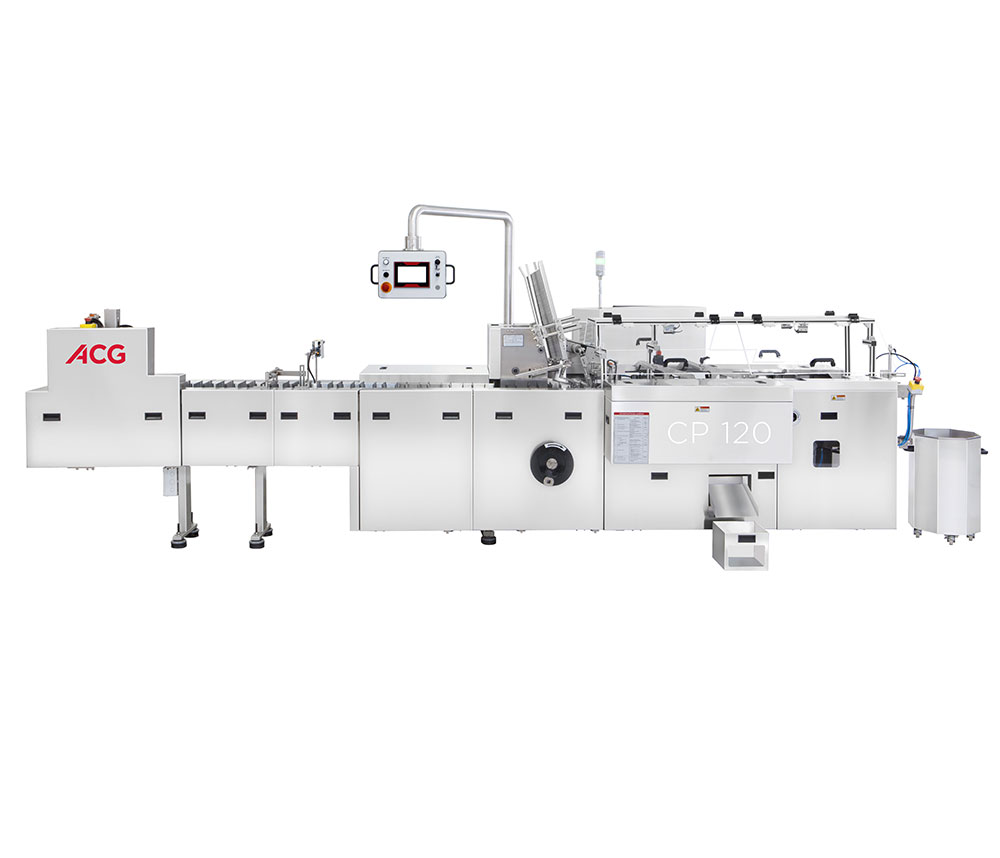

Related products

You can’t have healthy people without a healthy planet.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS