About the BQS E

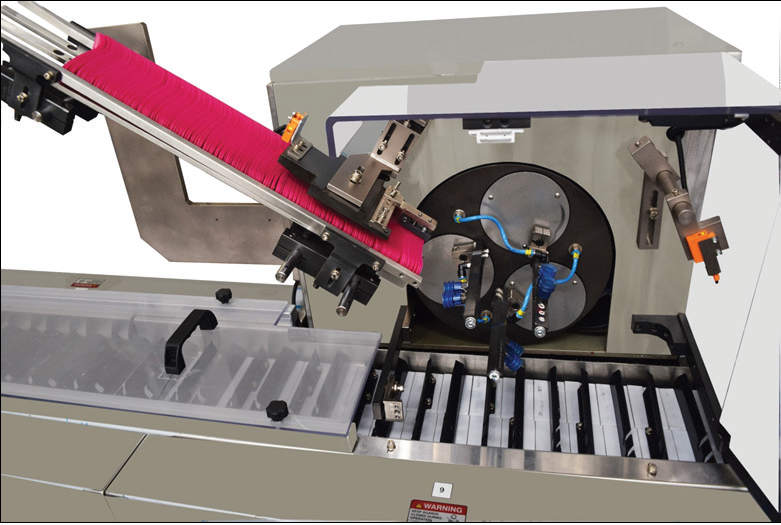

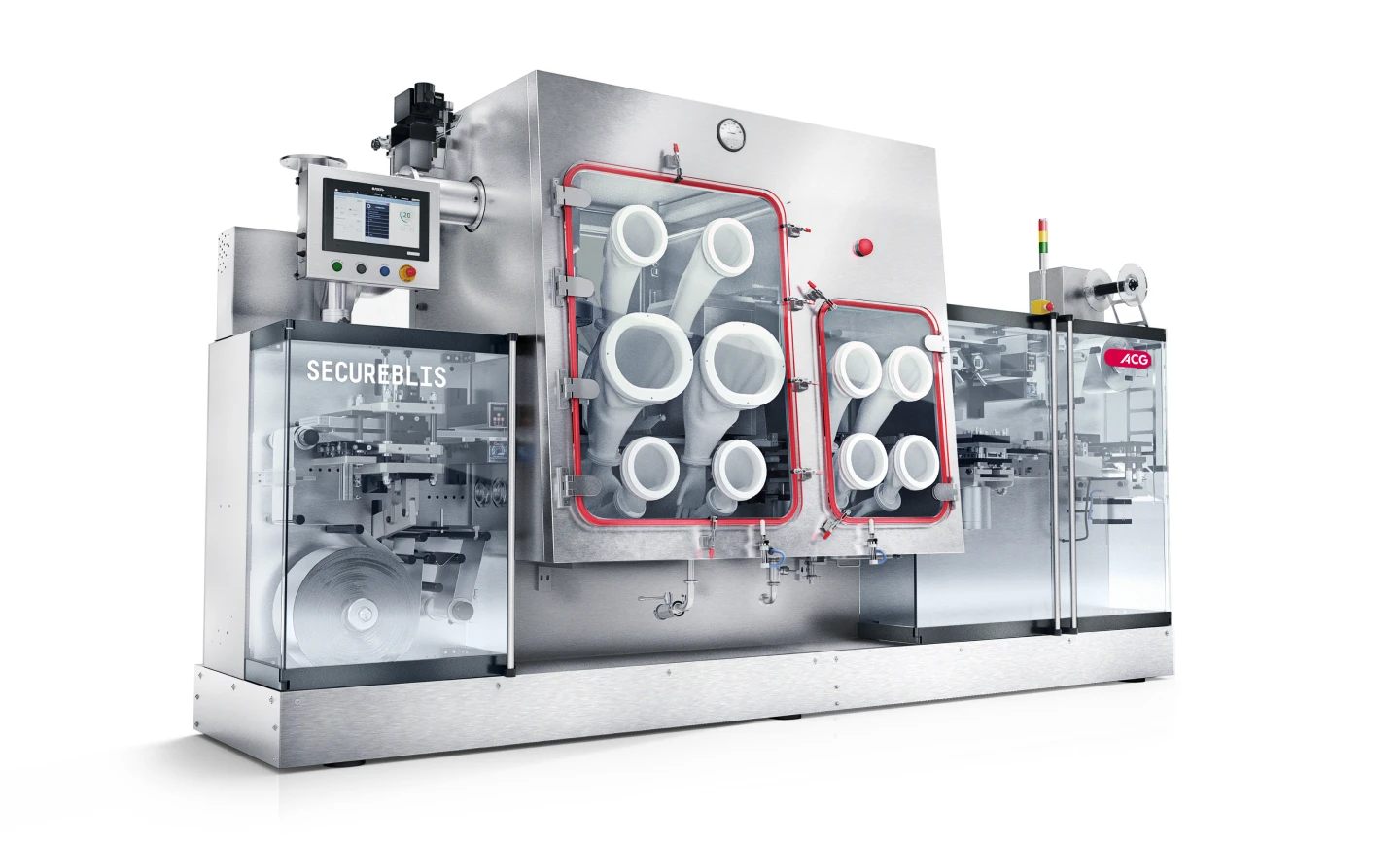

A workhorse machine for blister packaging, ACG’s BQS is increasingly first-choice among discerning manufacturers… and for good reasons. It now features the BQS E enclosure option, ensuring a safe packaging environment for solid dosage forms.

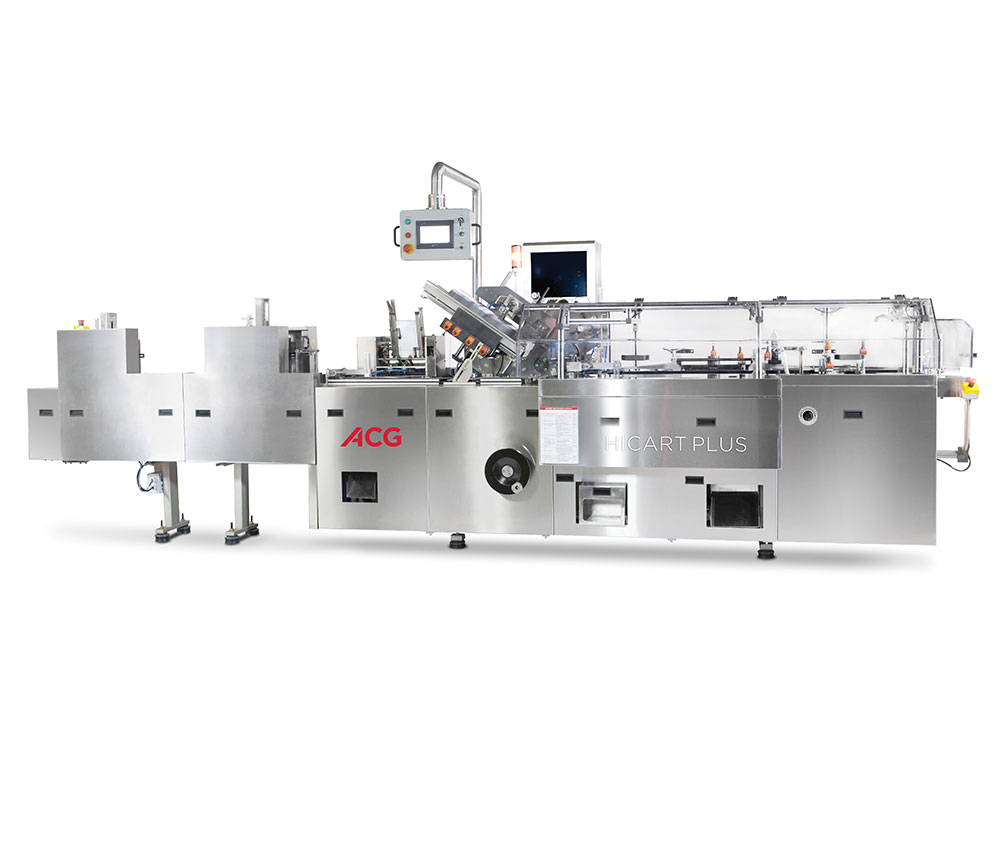

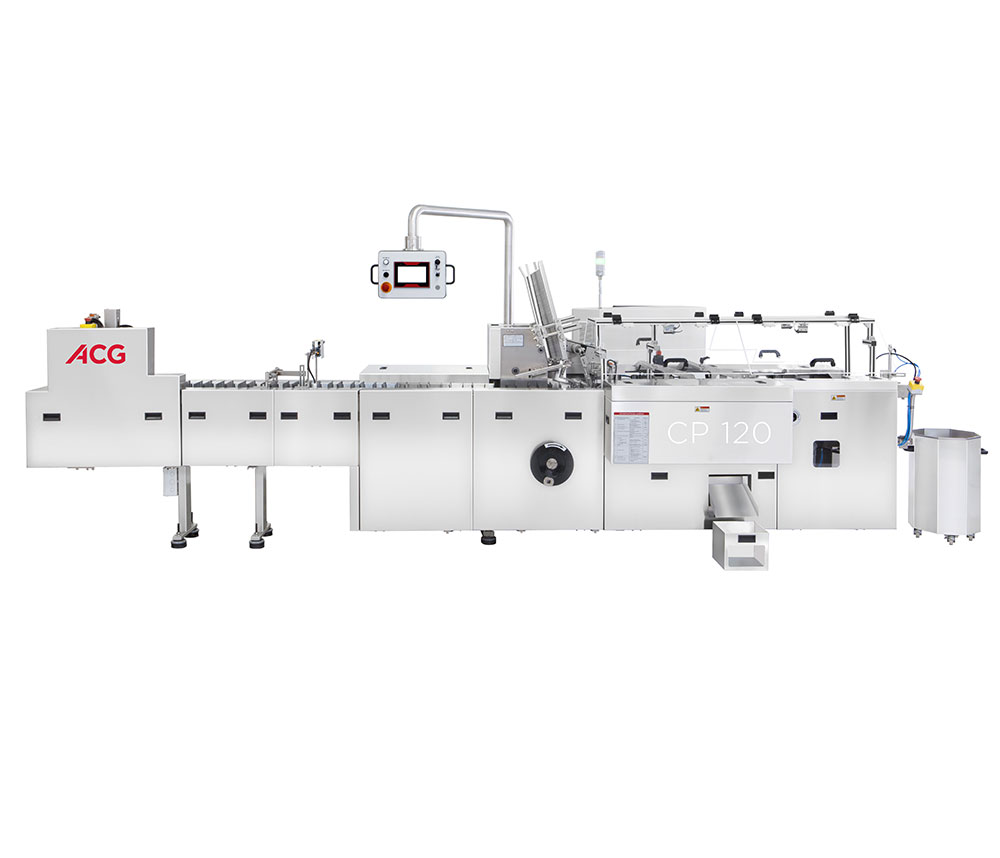

BQS E is a platen-sealing, continuous-motion machine capable of handling wide-ranging thermoform films and cold-form packaging foils. Powered by servo technology, it ensures accuracy, reliability, and precise control during blister packaging operations – and can be integrated with cartoners for seamless transitions from primary to secondary packaging.

Applications

Blister packaging of solid dosage products

| Features | Benefits | |

|---|---|---|

Enclosure design from forming to sealing, operating under negative pressure | Removes excessive particles from the working area | |

Rigid polycarbonate guarding for the entire machine | Full enclosure from feeding to sealing | |

Interlocks for all doors | Enhanced safety for operators | |

Can handle various thermoform films and cold-form packaging foils | Greater versatility | |

Differential pressure gauge for the filter and machine | Better in-process control | |

Effortless downstream integration with cartoners | Makes a viable solution for blister-cartoning lines |

Features & Benefits

Enclosure design from forming to sealing, operating under negative pressure

Removes excessive particles from the working area

Rigid polycarbonate guarding for the entire machine

Built-in glove ports

Full enclosure from feeding to sealing

Safer operator access

Interlocks for all doors

Enhanced safety for operators

Can handle various thermoform films and cold-form packaging foils

Greater versatility

Differential pressure gauge for the filter and machine

Better in-process control

Effortless downstream integration with cartoners

Makes a viable solution for blister-cartoning lines

Technical specification

| Forming cycle | Thermoforming | Up to 45 cycles/min |

| Cold-forming | Up to 35 cycles/min | |

| Forming depth | Thermoforming | Up to 12 mm |

| Cold-forming | Up to 9 mm | |

| Maximum forming area | 240 mm x 180 mm | |

| Forming materials | PVC, PVC/PVdC, Aclar, Triplex (PVC/PE/PVdC), cold-form foil (Alu) | |

| Lidding materials | Push-through foil, child-resistant foil, peelable foil | |

We make it better, so you make it better, and together we can help make the world better.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS